Boiler in paper mill | Paper steam boiler | Paper industry boiler

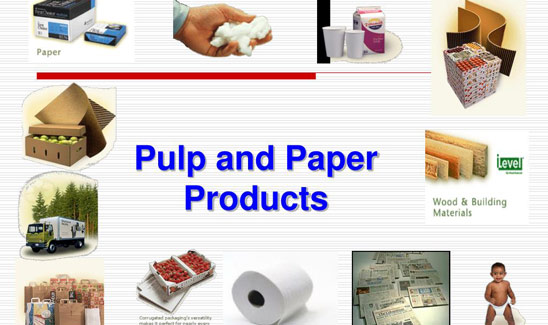

Boiler application in paper industry In paper production, a large amount of steam is required for heating and dissolving chemicals during pulping, product processing/forming, black pulp concentration, and pressing and drying. Therefore, the boiler is the main plant for the production of paper mills, and is an indispensable equipment for every paper mill. The boiler is used to generate high temperature steam, and then the steam is delivered to various workshops through sub-cylinders to achieve the purpose of heating and drying.

How to Choose the Suitable Boiler for Paper Factory

How to Choose the Suitable Boiler for Paper Factory

Industrial boilers can powered by 3 fuel type: 1. oil, gas, LPG, diesel, dual fuel; 2. Solid fuel like coal, biomass, wood, husks, pellets, palm shell, sawdust, charcoal etc... 3. Electricity

Confirm the heating capacity according to your production, by ton/hr, kw/h, Kcal/h, BHP is ok. If you don’t know, please contact us, we can calculate based on your production.

3 Transfer heat medium: steam, hot water, thermal oil. Normally, rice mill factory need steam for parboiling, drying etc. Paper boiler always use steam boiler

Choosing a boiler supplier is mainly based on the following aspects: company strength, main products and prices, quality control, export experience, technical support, installation and after-sales service.

What Boiler We Have for Paper Processing?

What Boiler We Have for Paper Processing?

350-28,000KW

Rated Thermal Power

4-38kg/㎡

Working Pressure

Biomass, Electric

Availiable Fuel

Service Life

Hot Sale Boilers for Paper Mill

Hot Sale Boilers for Paper Mill

DZL Chain Grate Steam Boiler

Capacity:1-10 ton/h

Fuel: rice husk, wood chips, straw, pellets, other biomass fuel

SZL Water Tube Steam Boiler

Capacity: 2-40 Ton/h

Fuel: Biomass, charcoal, firewood, woodchips, husks, shells, coal etc

WNS Oil Gas Fired Steam Boiler

Capacity: 1-20ton/h

Fuel: diesel, hfo, furnace oil, natural gas, lpg, dual fuel etc

Benefits

Benefits

From boiler solution, optimization to installation, 24 hours online, provide technical support and avoid risks for you

Based on user needs, we supply tailored service, boiler drawing&PID system, boiler room design, foundation drawings etc

Full-life After sale service. With our professional technical experts and service team, skilled technology provides customers with professional services

According to the customer production requirements, provide professional boiler solutions, cost analysis, project investment budget, boiler drawing&installation and commissioning service

Why you should choose Yuanda Boiler

Why you should choose Yuanda Boiler

High Level of Expertise

Quality Control

Strength & Certificates

After-sales Service

Product Scope

Customization

Send Your Message

Send Your Message

Please fill in your requirements for brochure, specifications, quotation. You will get a reply within 24 hours. Thanks.

Typical Scope of Supply

Contact Us Quickly