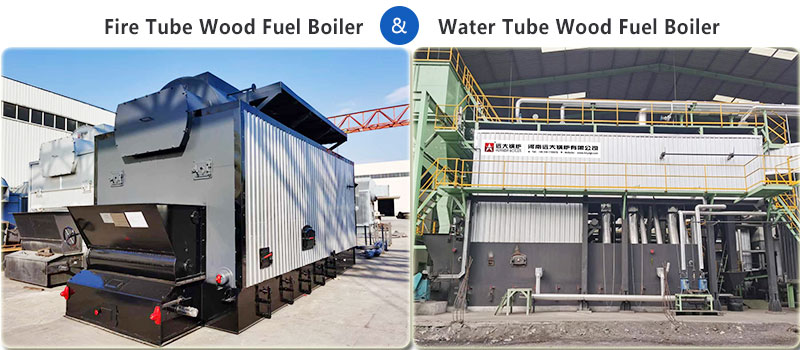

Horizontal wood boiler | Water tube wood boiler | Vertical wood boiler

Yuanda has DZL/DZH water-fire tube wood boiler and SZL/SZW water tube wood biomass boiler. Can produce saturated steam, superheated steam and hot water for factory production.

| Output: | steam, hot water |

| Capacity: | 100kg-50000kg, 0.1ton-50ton, 120kw-28000kw |

| Work Pressure: | 3-40bar, 0.3-4.0Mpa |

| Heat Temperature: | 0-450℃ |

| Applied Industry: | For heating/drying/turbine drive, in food, beverage, paper plant, textile mill, feed mill, pharm, package, chemical, building materials, laundry etc |

Introduction

Wood fired boiler is a kind of thermal equipment that uses firewood/wood-based fuel to heat water inside boiler then produce steam or hot water for factory production.

Yuanda Boiler's wood boiler is a category of industrial boilers, not a specific type of boiler. We design and manufactur different wood boiler based on fuel type, to meet various industrial heating and processing needs. It can minimize fuel costs and achieve high economic benefits.

These boiler features an upper furnace and a lower combustion chamber, modular design makes installation and maintenance easy. Could burning firewood, log, wood block, wood briquette, wood pellets, wood chip, sawdust, shavings, and mixed coal & wood fuel well.

There are two types: DZH horizontal firewood moving grate boiler, requires manual feeding and deslagging. LSG vertical firewood boiler, vertical design saves space. Small footprint, low investment cost.

Main characteristics:

● Patented threaded smoke tube has a self-sweeping capability, which improves heat transfer efficiency.

● Suitable for burning low-humidity, large-sized firewood, logs, biomass briquettes, wood bricks, etc.

● Pressure up to 20 kg/cm²

● Maximum steam output up to 6 ton(due to labor feeding)

● Packaged delivery, easy to install

● Low mechanical failure rate

There are two types: DZL fire tube structure wood boiler, SZL series water tube structure wood boiler. Wide fuel adaptability, especially suitable irregular wood fuels, mixed wood fuel, wood waste, wood chips, wood sawdust, wood sanding powder, wood shaving, high-moisture fuels, or blended fuels.

Main characteristics:

● Steam capacity 6-65ton/hr

● High efficiency

● No size limited, especially suitable irregular wood fuels, mixed bulk fuel, wood chips, bark, sawdust, shavings, high-moisture fuels etc

● Full membrane water-cooled wall structure

● Pressure up to 42 kg/cm²

● Three-stage combustion zone "preheating + main combustion + flameout".

● Reciprocating moving grate, active slag removal and self ash cleaning

One-stop boiler solution: Supply complete system including automatic feeding system, boiler body, combustion equipment, flue gas purification system, soft water treatment system, waste heat recovery system and PLC automatic control system.

High Fuel adaptability: Customized as customer neeed. Reduces fuel costs, and unaffected by fluctuations in a single fuel market.

High efficiency and reliability: Ensures continuous production and provides stable high-temperature, high-pressure steam.

Economical operation: Significantly saves investment and yields substantial long-term economic benefits.

Automation and intelligence: Reduces labor costs and operational complexity, and improves management efficiency.

Environmental compliance: Meets emission requirements and enhances the company's green image.

Yuanda's philosophy: "Quality First, Integrity Wins the World, and Common Development with Customers"

Company Strength

■ Founded in 1956, a premium supplier assessed, certified, and inspected by SGS Group. Leading industrial boiler manufacturer in China.■ Products sold to over 130 countries/regions, covering food, beverage, textiles, paper, wood industries. Serving over 100,000 customers.

Services & Markets

■ Local Support: We have long-term, reliable local agents, can provide one-stop service from installation and training to maintenance.■ High Repurchase Rate: 55% of our customers are repeat customers or referral customers.

Quality Assurance

(1) Strength calculation report with applied materials information;

(2) 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3) 100% X-ray inspection( (Longitudinal, transversal safety inspection)): ensure the quality of entire boiler;

(4) Hydrostatic test: ensure the standard working pressure and safety;

(5) Third-party inspection report

(6) Passed ASME CE ISO DOSH EAC GOST boiler level certificate.

Our Service

Pre-Sales Support:

Expert Design Guidance: Help you select the optimal boiler model tailored to your industry needs.Competitive Pricing: Factory-direct rates with uncompromised quality.

After-Sales Assurance:

Genuine Spare Parts: Original components with reliable supply.Parameter

| Model |

Rated steam output (Ton/hr) |

Rated steam pressure (Mpa) |

Rated steam temperature (℃) |

Feed water temperature (℃) |

Thermal efficiency(%) | Fuel consumption(Kg/h) |

| DZH 1 | 1 | 0.4/0.7/1.0/1.25/1.6/2.5 | 130~226 | 20/105 | >81 | 140 |

| DZH 2 | 2 | 0.4/0.7/1.0/1.25/1.6/2.5 | 130~226 | 20/105 | >81 | 280 |

| DZH 4 | 4 | 0.4/0.7/1.0/1.25/1.6/2.5 | 130~226 | 20/105 | >81 | 570 |

| DZH 6 | 6 | 0.4/0.7/1.0/1.25/1.6/2.5 | 130~226 | 20/105 | >81 | 810 |

| DZH 8 | 8 | 0.4/0.7/1.0/1.25/1.6/2.5 | 130~226 | 20/105 | >81 | 1100 |

| DZL 10 | 10 | 0.4/0.7/1.0/1.25/1.6/2.5/3.0/3.82 | 130~304 | 20/105 | >84 | 1380 |

| DZL 15 | 15 | 0.4/0.7/1.0/1.25/1.6/2.5/3.0/3.82 | 130~304 | 20/105 | >84 | 2100 |

| DZL 20 | 20 | 0.4/0.7/1.0/1.25/1.6/2.5/3.0/3.82 | 130~304 | 20/105 | >84 | 2600 |

| Note: Standard boiler parameter is for your reference, should follow the actual technical data according customer needs & engineer design. | ||||||

Relate Cases

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler