Thermic fluid heater | Organic heat transfer boiler | Hot oil heating boiler

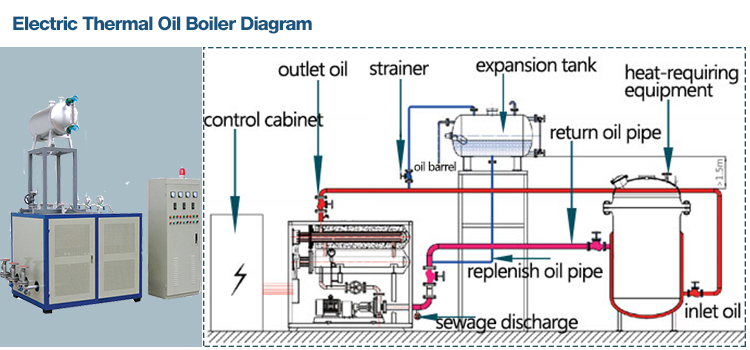

GYD electric thermal oil heater is an environmentally thermal energy conversion equipment. The heating element is directly inserted into the thermal fluid oil for direct heating, then circulation pumps is used to force the thermal oil to circulate in liquid phase, transferring the heat to one or more heating devices.

| Thermal Capacity: | 10 to 1400kw |

| Heating Capacity: | 8000kcal to 1200,000kcal |

| Temperature: | max 400 ℃ |

| Pressure: | below 10bar |

| Applied Industries: | printing, dyeing, refinery&chemical, plastic and rubber, wood industry, building material, food industry, etc. |

GYD electric oil heater, also named hot oil heating system that use thermal oil or edible oil as medium. The fluid oil is heated in the boiler tubes then transferring heat to one or more heat-using devices at factory, output high temperature oil continuously for end user.

Rated Pressure: 0.6mpa/0.8mpa/1.0mpa

Rated Temperature: can be adjusted, max. 350℃

The whole system includes electric oil heater, centrifugal pump, expansion tank, control center, oil-gas separator, stop valves, platinum resistance thermometer sensor, pressure gauge with electric contact, alumina silicate fibre insulation and connecting piping mounted on a welded steel base.

Working Principle

●Uses electricity as energy, converts electric energy into heat energy through electric heating elements, no emission worried.

●Use thermal fluid as heat transfer medium, the circulating oil pump to force the thermal oil to circulate in liquid phase

●After passing through the heating device, it returns to boiler by circulation pump. Repeatedly, increase the temperature of the heated object.

●Meet the seted temperature and high-precision temperature control

●Using electric energy as power, clean and environmentally friendly, no smoke, no pollution, no impact on the health of operators

●Easy to install, automatic control, no need labor

●Cabinet appearance, beautiful appearance, compact internal structure, saving space, no need for a dedicated boiler room

●RS485 communication function to realize remote automatic control & data collection (optional)

●The electric heating tube is connected to the furnace body with a flange, which is convenient for replacement, repair and maintenance.

●Effective temperature control system, stable heating and accurate temperature adjustment ±1℃.

●Thermal efficiency reaches over 95%.

●Explosion-proof level: Exd II BT4, protection level: IP54.

●Electrical appliances adopt OMRON.SIEMENS.BAELZ.FUJI.RKC.

●Safer and more convenient than burning coal, oil or natural gas

●Provide customers with one-stop service of designing, manufacturing and installing mechanical heat carrier furnaces, and deliver them directly to customers for use.

Yuanda's philosophy: "Quality First, Integrity Wins the World, and Common Development with Customers"

Company Strength

■ Founded in 1956, a premium supplier assessed, certified, and inspected by SGS Group. Leading industrial boiler manufacturer in China.■ Products sold to over 130 countries/regions, covering food, beverage, textiles, paper, wood industries. Serving over 100,000 customers.

Products & Technology

■ Diverse Product Range: Fire-tube boilers, water-tube boilers, water-fire-tube boilers, combined boilers, vertical boilers, cogeneration boilers, waste heat recovery boilers, skid-mounted boilers, and mobile containerized boilers.■ Collaboration with advanced boiler research institutes ensures advanced technology and high energy efficiency.

Services & Markets

■ Local Support: We have long-term, reliable local agents, can provide one-stop service from installation and training to maintenance.■ High Repurchase Rate: 55% of our customers are repeat customers or referral customers.

Quality Assurance

(1) Strength calculation report with applied materials information;

(2) 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3) 100% X-ray inspection( (Longitudinal, transversal safety inspection)): ensure the quality of entire boiler;

(4) Hydrostatic test: ensure the standard working pressure and safety;

(5) Third-party inspection report

One-stop Boiler Solution

Comprehensive Boiler Solutions – From Planning to Lifetime Support

Pre-Sales Support:Expert Design Guidance: Help you select the optimal boiler model tailored to your industry needs.

Detailed Technical Documentation: Provide certificates, CAD drawings, consumption analysis, and boiler room planning.

Customized Solutions: Deliver complete system designs including installation material lists.

Competitive Pricing: Factory-direct rates with uncompromised quality.

After-Sales Assurance:Genuine Spare Parts: Original components with reliable supply.

Global Installation & Commissioning: Overseas engineer dispatch available.

On-Site Training: Ensure safe and efficient operation.

24/7 Online Support: Rapid response for any technical needs.

Warranty & Lifelong Care: One-year free maintenance and lifetime service support.

Parameter

| model | thermal capacity | pressure | size | weight | expansion tank | |||

| (KW) | (*104kcal/h) | (Mpa) | L | W | H | Kg | L | |

| GYD10 | 10 | 0.8 | 0.6 | 1100 | 500 | 1100 | 200 | 100 |

| GYD18 | 18 | 1.5 | 0.6 | 1600 | 500 | 1250 | 200 | 130 |

| GYD24 | 24 | 2 | 0.6 | 1950 | 650 | 1450 | 350 | 150 |

| GYD36 | 36 | 3 | 0.6 | 1950 | 650 | 1450 | 350 | 200 |

| GYD48 | 48 | 4 | 0.6 | 1950 | 650 | 1450 | 350 | 230 |

| GYD60 | 60 | 5 | 0.6 | 1950 | 650 | 1450 | 350 | 230 |

| GYD70 | 70 | 6 | 0.6 | 2150 | 700 | 1750 | 550 | 280 |

| GYD90 | 90 | 7.5 | 0.6 | 2150 | 700 | 1750 | 550 | 280 |

| GYD120 | 120 | 10 | 0.6 | 2200 | 700 | 1880 | 750 | 300 |

| GYD150 | 150 | 12.5 | 0.6 | 2200 | 900 | 1880 | 750 | 300 |

| GYD180 | 180 | 15 | 0.6 | 2200 | 1000 | 1880 | 1200 | 320 |

| GYD240 | 240 | 20 | 0.6 | 2300 | 1000 | 1950 | 1200 | 350 |

| GYD300 | 300 | 25 | 0.6 | 2800 | 1200 | 2000 | 1750 | 450 |

| GYD500 | 500 | 40 | 0.6 | 2800 | 1500 | 2000 | 1850 | 550 |

| GYD600 | 600 | 50 | 0.6 | 3000 | 1800 | 2150 | 1950 | 600 |

| GYD700 | 700 | 60 | 0.6 | 3000 | 1800 | 2150 | 2200 | 650 |

| … | … | … | … | … | … | … | … | … |

| GYD1400 | 1400 | 120 | 0.6 | 3600 | 2900 | 2150 | 6500 | 1200 |

Relate Cases

Recommend Boiler

YY(Q)W Thermal Oil Boiler

Horizontal oil gas fired hot oil heater boiler, fully automatic, low pressure with stable heating

YGL Oil Heater

Vertical thermal oil heater, Small footprint, low cost, quick into use

YLW Hot Oil Boiler

Horizontal coal bioamass fired heating oil boiler, grate stoker, running stable

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler