Solid Fuel Boiler | Horizonal Packaged Boiler | 3-pass Water-fire Tube Boiler

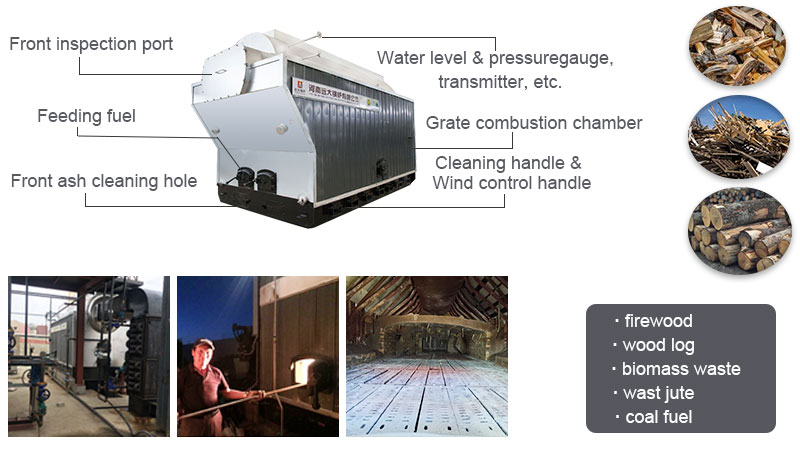

DZH solid fuel fired boiler is a horizontal hand-fired boiler, water tube structure with moving grate. It can burning kinds of solid fuel, firewood, waste wood, briquette, charcoal, waste jute etc. Strong fuel adaptability, stable operation and high cost performance.

| Model: | DZH DZL |

| Capacity Range: | 0.5ton/h to 20ton/h, 350 to 14,000 kw |

| Output: | saturated steam, hot water |

| Style: | Manual feeding |

| Applied Industry: | food&beverage, dairy, feed, textile, paper, chemical, package, refinery, pharm, building material, hotel etc |

Introduction

DZH solid fuel fired boiler is a horizontal hand-fired boiler, water tube structure with moving grate. It can burning well with various solid fuels such as coal, firewood, waste wood, briquettes, charcoal, waste fabric&jute, etc. Strong fuel adaptability, stable operation and low running cost.

This boiler can produce 0.2-2.5mpa steam or hot water for factory use. Application: food, beverage, dairy, feed, tea, textile, paper, chemical, package, refinery, pharm, building material, hotel and many other industry;

DZH hand fired boiler also known as packaged boiler, traveling grate boiler and water & fire tube boiler. Steady safe operation and long lifetime, has the features of "hand-cranked movable grate" "two wings-shape flue" "convex tube plate" "inertia gas-dust separation" etc, all make boilers superior, less mechanical failure

Easy install and operating: Experienced engineers supported & perfect after-sale service guarantee, boiler system could be well-debugged.

Over pressure, over temperature, low water level, air ignition alarmming and interlock.

Characteristics

01

Three pass gas flue structure & Arched tube plate

1. Three pass design extends the flue gas distance, strengthen the thermal transfer efficiency; 2. Arched tube plate increases the toughness of the tube sheet, prevent end cover cracking

02

Spiral Fire Tubes(Smoke Tube) Technology

Use the advanced technology which is our patent to design the spiral tubes, to enhance the boiler thermal power 10% higher than normal, and avoid the spiral tube from ash deposition and wearing

03

Fully automatic chain grate combustion

Use big piece fire grate, air supply sufficient and evenly, tight connection, almost no leakage, avoid loss of calorific value and affect boiler thermal efficiency

04

Economizer Design, Energy Saving

1. Recycle exhausted smoke to heat feed water, increase feed water temp then save fuel cost at least 6% per hour 2. Reduce chimney smoke temperature

About Our Comapny

■ Established in 1956, as a stated owned enterprise.

■ Over 16 years export experiences, payment & shipping protection

■ CE ASME DOSH EAC GOST ISO high standard boiler certified

■ Production of various types boilers, provide pre-sale boiler proposal for customer select

■ Directly factory low price & quality protection.

■ Completed technology & after-sale service team.

■ Support Video/VR inspection. Abroad installation and commissing service etc

■ Technical discussion, drawing about boiler solution for your company use

Parameter

| Model |

Rated steam output (Ton/hr) |

Rated steam pressure (Mpa) |

Rated steam temperature (℃) |

Feed water temperature (℃) |

Thermal efficiency(%) | Fuel consumption(Kg/h) |

| DZH 1 | 1 | 0.4/0.7/1.0/1.25/1.6/2.5 | 130~226 | 20/105 | >81 | 140 |

| DZH 2 | 2 | 0.4/0.7/1.0/1.25/1.6/2.5 | 130~226 | 20/105 | >81 | 280 |

| DZH 4 | 4 | 0.4/0.7/1.0/1.25/1.6/2.5 | 130~226 | 20/105 | >81 | 570 |

| DZH 6 | 6 | 0.4/0.7/1.0/1.25/1.6/2.5 | 130~226 | 20/105 | >81 | 810 |

| DZH 8 | 8 | 0.4/0.7/1.0/1.25/1.6/2.5 | 130~226 | 20/105 | >81 | 1100 |

| DZL 10 | 10 | 0.4/0.7/1.0/1.25/1.6/2.5/3.0/3.82 | 130~304 | 20/105 | >84 | 1380 |

| DZL 15 | 15 | 0.4/0.7/1.0/1.25/1.6/2.5/3.0/3.82 | 130~304 | 20/105 | >84 | 2100 |

| DZL 20 | 20 | 0.4/0.7/1.0/1.25/1.6/2.5/3.0/3.82 | 130~304 | 20/105 | >84 | 2600 |

| Note: Standard boiler parameter is for your reference, should follow the actual technical data according customer needs & engineer design. | ||||||

Relate Cases

Recommend Boiler

SZL Water Tube Biomass boiler

Double drum chain grate burning solid fuel boiler, full membrane wall, automatic feeding

DZL Biomass Boiler

Chain grate single drum boiler, automatic biomass boiler

WNS Oil Gas Fired Boiler

Horizontal 3-pass fire tube boiler with famous burner. Energy saving, 99% efficiency

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler