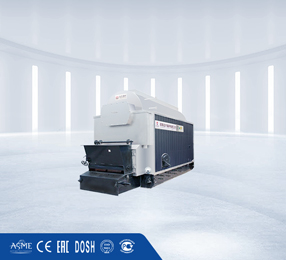

Biomass steam/hot water boiler | Water tube boiler | Membrane wall boiler

SZL series boiler is double drum boiler with seamless full membrane wall, grate combustion burning, can produce steam for industrial production. Also our company designing SZL-D type boiler most suitable for biomass fuel.

| Output: | steam/hot water |

| Capacity: | 2-50 ton/h |

| Horsepower | 10hp to 2500hp |

| Available Fuel: | coal, biomass, woodchips, palm shell/fiber, bagasse, sawdust, husks etc |

| Applied Industries: | for heating/drying/turbine, in food/beverage, paper, package, textile, feed mill, chemical, building, hotel, laundry etc |

Introduction

SZL biomass boiler is a water tube structure boiler, longitudinally double drum boiler, combustione device is chain grate or reciprocating grate(step grate).

SZL series water tube boiler can fueled by wood, biomass, coal, palm kernel shells, coconuts shell, rice husks, sawdust, bagasse.

Has SZL-A & SZL-D types, especially SZL-D type is our company patented feature product. High technology, environmental and energy saving.

SZL Core Technology

★ Whirlwind burning chamber structure

★ Indenpend wind chamber structure and secondary wind burning

★ Fron-rear water-cooled arch design

★ Large furnace capacity, wid biomass fuel adaptablity

★ Membrane water wall construction

★ Double 12cm Layer Aluminum silicate insultion

★ 5 stage water level and pressure protection, automatic interlock device

BOILER Advantages Of

① Offset furnace design, 15% bigger furnace combustion, the heated area increases along.

② Membrane type furnace wall, not easy to collapse, good airtightness, no deformation, no dust falling

③ Best wind adjust design, segmented air supply (preheating zone, drying zone, main combustion zone, coke zone, ash slag zone) can freely adjust the air volume

④ Secondary cyclone burnout chamber, reduce fuel cost, save running cost, improve boiler thermal efficiency

⑤ Built-in dust removal device inside boiler, effectively solve the problem of coking, low original dust discharge concentration

⑥ Equipped energy-saving device like economizer/preheater/cyclon/wet scrubber, environmental protection and energy conservation

⑦ Recommended suitable grate materials, and chain grate, reciprocating grate, or water cooling vibrating grate, according the fuel features.

About Yuanda Boiler

■ Established in 1956, as a stated owned enterprise.

■ Over 16 years export experiences, payment & shipping protection

■ CE ASME DOSH EAC GOST ISO high standard boiler certified

■ Production of various types boilers, provide pre-sale boiler proposal for customer select

■ Directly factory low price & quality protection.

■ Completed technology & after-sale service team.

■ Support Video / VR factory-inspection. Abroad installation and commissing service etc

■ Technical discussion, drawing about boiler solution for your company use

Service

WELCOME Contact Us for Boiler Information

Just please confirm 4 points as bellow, we will offer the appropriate boiler model for you, with price, specifications, running pictures.

1. How many ton/kg/kw/hp/kcal capacity you need?

2. What steam pressure or working temperature you need?

3. What fuel you plan to use?

4. What factory will you use the steam generator?

Parameter

| Boiler model | Rated capacity | Rated | Rated steam temp. | Feed water temp. | Exhaust gas temp. | Design effiency | Boiler water volume | Weight | Dimension | Delivery mode |

| pressure | ||||||||||

| ton/h | Mpa | ºC | m2 | ºC | % | m3 | ton | mm | ||

| SZL2 | 2 |

1.25/1.6/1.8/ 2.5/3.82 |

194/204/ 226/300/350/450 |

20/105 | 130.67 | 83.13 | 6.76 | 22 | 5900×2850×3460 | Package |

| SZL4 | 4 | 142 | 84.23 | 5.1 | 29 | 6460×3280×3462 | Package | |||

| SZL6 | 6 | 142 | 84.81 | 8.4 | 34 | 7830×3560×3462 | Package | |||

| SZL8 | 8 | 149.15 | 85.02 | 9.4 | 40.5 | 8870×3670×3462 | Package | |||

| SZL10 | 10 | 152.7 | 86.2 | 8.35 | 24 | 7645×3180×3526 | Assembly | |||

| SZL12 | 12 | 148.7 | 86.56 | 12.8 | 37 | 9258×3294×3524 | Assembly | |||

| SZL15 | 15 | 149.86 | 86.29 | 15.5 | 24.7 | 11010×3300×2200 | Assembly | |||

| SZL20 | 20 | 147.4 | 86.8 | 15.8 | 25.97 | 16680×6200×8420 | Assembly | |||

| SZL25 | 25 | 149.6 | 86.4 | 16.5 | 28 | 8300×3000×3600 | Semi-Assembly | |||

| SZL30 | 30 | 148.6 | 86.8 | 16.8 | 29 | 8500×3600×3640 | Semi-Assembly | |||

|

Notice: For place limited, we didnot list all models. Please contact us directly for get specifics. |

||||||||||

Relate Cases

Recommend Boiler

DZL Coal boiler

Single drum chain grate burning solid fuel boiler, water&fire tube boiler, fully automatic

WNS Oil Gas Fired Boiler

Horizontal 3-pass fire tube boiler with famous burner. Energy saving

DZH Coal/Wood Boiler

Traveling grate boiler, hand-feed, running stable, suitable for bigger solid fuel

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler