Chain grate boiler| Reciprocating grate boiler | Moving grate boiler

Yuanda biomass boiler, using chain grate or reciprocating grate or fixed grate as combustion device, burn woodchip, pellet, firewood, ricehusk, fruit shell etc. We aim to offer the most proper biomass boiler according fuel.

| Capacity: | 100kg-50000kg, 0.1ton-50ton, 120kw-28000kw |

| Work Pressure: | 3-40bar, 0.3-4.0Mpa |

| Heat Temperature: | 0-450℃ |

| Output: | Steam, Hot Water |

| Application: | For heating/drying/turbine drive, in food, beverage, paper, textile, feed mill, pharm, package, chemical, building materials, laundry etc |

Introduction

Biomass fired boiler is a kind of thermal equipment that uses wood/biomass-based fuel to heat water inside boiler then produce steam or hot water for factory production line.

Yuanda Boiler's biomass boiler is a category of industrial boilers, not a specific type of boiler. We design and manufactur different biomass boiler based on fuel type, to meet various industrial heating and processing needs. It can minimize fuel costs and achieve high economic benefits.

These boiler features an upper furnace and a lower combustion chamber, modular design makes installation and maintenance easy. Could efficiently and environmentally burn firewood, tree bark, log, pellet, briquette, wood chips, sawdust, shavings, timber waste, coffee husks, waste fabric, olive pomace, rice husk, EFB&palm fiber, cashew nut shells, walnut shells, and bagasse.

"LSG series" Vertical Boiler

LSG vertical boiler also known as small wood biomass boiler. It is the vertical fixed grate boiler with water tube. It can burn firewood, log, coal, biomass, waste jute, charcoal, pellets.

Vertical design saves space, manual feeding, reduce mechanical failures, easy to install and operate.

SZL/SZW series boiler is horizontal double-drum, water tube structure assembled boiler.

Features:

1. Full membrane water-cooled wall structure, stable and efficient operation.

2. Custom-made according to fuel, configure different combustor (chain grate, moving grate, traveling grate, reciprocating grate, bubbling bed grate).

3. Three-stage combustion zone "preheating + main combustion + burn out".

4. Wide fuel adaptability, no size limited. Particularly suitable for mixed biomass fuels and high-moisture fuels, irregular bulk fuel.

5. Active slag removal and self ash cleaning, low ash accumulation.

6. With energy saving device and dust collector system, sufficient output, low emission.

7. Modular design makes installation and maintenance simple.

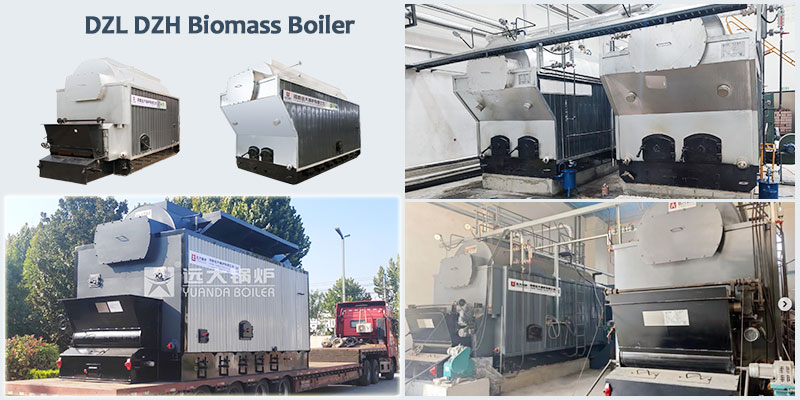

"DZL series" Biomass Boiler

DZL and DZH boilers, is horizontal water & fire tube packgaed steam boiler. It is also called: a revolution in industrial boilers.

Features:

1. The upper furnace and combustor are packaged before delivery, quick installation, less investment.

2. Manual type traveling grate available, support hand feeding to reduce cost.

3. Due to packaged design, max steam capacity up to 8 ton, heating power up to 5600kw.

4. Spirally corrugated fire tubes, improves thermal efficiency, reduces flue gas temperature.

5. Wing-shape flue, allows smoke to enter the front smoke box smoothly, prevents tube sheet damage.

6. "α"-shaped flue gas recirculation and secondary air distribution technology.

One-stop boiler solution: Supply complete system including feeding system, boiler body, combustion equipment, flue gas purification system, soft water treatment system, waste heat recovery system and PLC automatic control system.

High Fuel adaptability: Different fuel, different solution. Reduces fuel costs, and unaffected by fluctuations in a single fuel market.

High efficiency and reliability: Ensures continuous production and provides stable high-temperature, high-pressure steam.

Economical operation: Significantly saves investment and yields substantial long-term economic benefits.

Automation and intelligence: Reduces labor costs and operational complexity, and improves management efficiency.

Environmental compliance: Meets emission requirements and enhances the company's green image.

Yuanda's philosophy: "Quality First, Integrity Wins the World, and Common Development with Customers"

Company Strength

■ Founded in 1956, a premium supplier assessed, certified, and inspected by SGS Group. Leading industrial boiler manufacturer in China.■ Products sold to over 130 countries/regions, covering food, beverage, textiles, paper, wood industries. Serving over 100,000 customers.

Products & Technology

■ Diverse Product Range: Fire-tube boilers, water-tube boilers, water-fire-tube boilers, combined boilers, vertical boilers, cogeneration boilers, waste heat recovery boilers, skid-mounted boilers, and mobile containerized boilers.■ Collaboration with advanced boiler research institutes ensures advanced technology and high energy efficiency.

Services & Markets

■ Local Support: We have long-term, reliable local agents, can provide one-stop service from installation and training to maintenance.■ High Repurchase Rate: 55% of our customers are repeat customers or referral customers.

Quality Control

(1) Strength calculation report with applied materials information;

(2) 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3) 100% X-ray inspection( (Longitudinal, transversal safety inspection)): ensure the quality of entire boiler;

(4) Hydrostatic test: ensure the standard working pressure and safety;

(5) Third-party inspection report

(6) Passed ASME CE ISO DOSH EAC GOST boiler level certificate.

Our Service

Comprehensive Boiler Solutions – From Planning to Lifetime Support

Pre-Sales Support:Expert Design Guidance: Help you select the optimal boiler model tailored to your industry needs.

Detailed Technical Documentation: Provide certificates, CAD drawings, consumption analysis, and boiler room planning.

Customized Solutions: Deliver complete system designs including installation material lists.

Competitive Pricing: Factory-direct rates with uncompromised quality.

After-Sales Assurance:Genuine Spare Parts: Original components with reliable supply.

Global Installation & Commissioning: Overseas engineer dispatch available.

On-Site Training: Ensure safe and efficient operation.

24/7 Online Support: Rapid response for any technical needs.

Warranty & Lifelong Care: One-year free maintenance and lifetime service support.

Parameter

| Model |

Steam output (Ton per hour) |

Rated steam pressure (Mpa) |

Rated steam temperature (℃) |

Feed water temperature (℃) |

Thermal efficiency (%) |

Fuel consumption (Kg/h) |

| DZL 1 | 1 ton | 0.4 to 2.5 mpa | 130~226 ℃ | 20/105 ℃ | >86 | 150 |

| DZL 2 | 2 ton | 0.4 to 2.5 mpa | 130~226 ℃ | 20/105 ℃ | >86 | 280 |

| DZL 4 | 4 ton | 0.4 to 2.5 mpa | 130~226 ℃ | 20/105 ℃ | >86 | 570 |

| DZL 6 | 6 ton | 0.4 to 2.5 mpa | 130~226 ℃ | 20/105 ℃ | >86 | 810 |

| DZL 8 | 8 ton | 0.4 to 2.5 mpa | 130~226 ℃ | 20/105 ℃ | >86 | 1100 |

| DZL 10 | 10 ton | 0.4 to 2.5 mpa | 130~226 ℃ | 20/105 ℃ | >86 | 1380 |

| DZL 15 | 15 ton | 0.4 to 2.5 mpa | 130~226 ℃ | 20/105 ℃ | >86 | 2100 |

| DZL 20 | 20 ton | 0.4 to 2.5 mpa | 130~226 ℃ | 20/105 ℃ | >86 | 2600 |

| Note: Standard boiler parameter is for your reference, should follow the actual technical data according customer needs & engineer design. | ||||||

| Model |

Rated heating capacity (mw) |

Rated working pressure (Mpa) |

Rated output water temperature (℃) |

Rated return water temperature (℃) |

Thermal efficiency (%) |

Fuel consumption (Kg/h) |

| DZL 0.7 | 0.7mw | Atmospheric pressure/0.7/1.0 mpa | 85/95/115/130 ℃ | 70/60 ℃ | >84 | 150 |

| DZL 1.4 | 1.4mw | Atmospheric pressure/0.7/1.0 mpa | 85/95/115/130 ℃ | 70/60 ℃ | >84 | 302 |

| DZL 2.8 | 2.8mw | Atmospheric pressure/0.7/1.0 mpa | 85/95/115/130 ℃ | 70/60 ℃ | >84 | 596 |

| DZL 4.2 | 4.2mw | Atmospheric pressure/0.7/1.0 mpa | 85/95/115/130 ℃ | 70/60 ℃ | >84 | 880 |

| DZL 5.6 | 5.6mw | Atmospheric pressure/0.7/1.0 mpa | 85/95/115/130 ℃ | 70/60 ℃ | >84 | 1160 |

| DZL 7 | 7mw | Atmospheric pressure/0.7/1.0 mpa | 85/95/115/130 ℃ | 70/60 ℃ | >84 | 1380 |

| DZL 10.5 | 10.5mw | Atmospheric pressure/0.7/1.0 mpa | 85/95/115/130 ℃ | 70/60 ℃ | >84 | 2030 |

| DZL 14 | 14mw | Atmospheric pressure/0.7/1.0 mpa | 85/95/115/130 ℃ | 70/60 ℃ | >84 | 2700 |

| Note: for place limited, we didn't list all models, if you need other capacity, pressure, fuel, please send us inquiry directly, we will send you detailed parameter. | ||||||

Relate Cases

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler