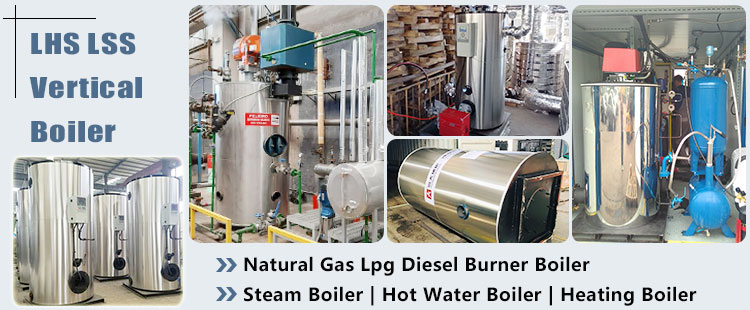

Gas diesel steam generator | Vertical steam boiler | Vertical ot water boiler

LHS vertical gas or oil fired boiler is a kind of fire tube boiler, vertical type industrial boiler, high efficiency, energy saving and space saved. It could provide steam or hot water for factory production.

| Output: | steam, hot water |

| Capacity: | 100-2000kg 120-1400kw 0.1-2ton |

| Horsepower | 10-150hp boiler |

| Fuel: | natural gas, lpg, biogas, diesel, heavy oil, dual fuel |

| Used: | for food, beverage, diary, milk, feed mill, refinery, chemical, slaughterhouse, laundry, hotel, greenhouse, etc |

Introduction

LHS LSS vertical oil gas boiler, is a upright small scale steam and hot water boiler. Fast heat up, 96% high efficiency. It is the leader among similar boiler products.

Pressure: 0.4mpa 0.7mpa 1.0mpa(4bar-10bar)

Capacity: 0.1ton-2ton, 100kg-2000kg, 90kw-1400kw, 10hp-150hp.

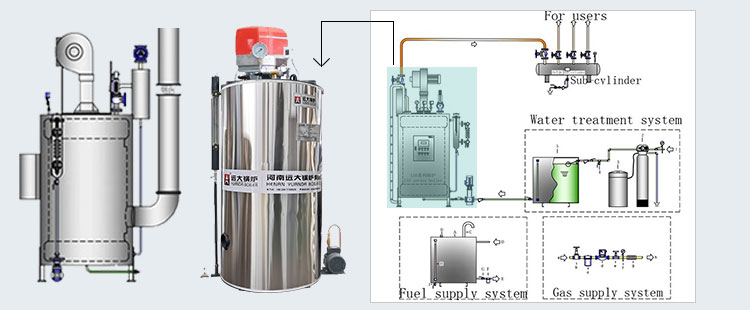

●Automatic Vertical FireTube Boiler.(LSS type is water tube)

●Three pass, larger corugated furmace, thread smoke tube with unique expansion welding.

●International first-level brand burners.

●Utilize energy-saving devices such as economizer/condenser/heat recovery unit.

●High-matching PLC English/Russia/Spanish control system realizes muitiple linkages, easy to operate, operating safely for 20+years.

7. Provide whole system, composed by boiler body, water treatment, burner and boiler control system.

Pre-sale Service:

1. Design

We help customer to choose the best boiler model according to the different requirements of different industries.

2. Drawing and files

Supply quality certificates, factory-inspect, fuel consumption calculation, cost analysis, foundation drawings, layout drawings, boiler room drawings nased on your needs, etc.

3. Technical Solution

Design completed boiler solution with installation materials for your company.

4. Transportation

We have shipping partners and forwarder for lowest price and safe.

After-sale Service:

1. Provide a full range of boiler and original spare parts.

2. Overseas engineers installation and commissioning service is available.

3. Training in site, to ensure safe operation.

4. 24 hours online, quick respond.

5. Free maintenance and repair for one year and lifetime service.

Quality Assurance

Steel element test→Steel rust cleaning→Welding electrodes drying process→Automatic welding, argon arc welding, expansion welding etc. methods→NDT(Nondestructive Testing) including X-ray Test, Ultrasonic Test, Magnetic particle Test→Hydraulic pressure test.

FAQ of Vertical Boiler

1. How much gas does the boiler use per hour?

Take 1 ton natural gas boiler as an example, the consumption per hour is 70m³/h.

2. Worried about the installation?

①We have skid mounted gas boiler, free of installation; ②We can send engineers to install boiler.

3. Do you have agent here?

We have agents and partners in some countries, will check list for you.

Parameter

| Boiler Model | LHS0.1 | LHS0.2 | LHS0.3 | LHS0.5 | LHS0.7 | LHS1 | |

| Rated steam capacity(t/h) | 0.1 | 0.2 | 0.3 | 0.5 | 0.7 | 1 | |

| Horsepower | 7hp | 15hp | 20hp | 35hp | 50hp | 70hp | |

| Rated steam pressure(Mpa) | 0.4 | 0.4 | 0.4 | 0.4/0.7 | 0.4/0.7 | 0.4/0.7 | |

| Rated steam temperature(ºC) | 151 | 151 | 151 | 151(170) | 151(170) | 151(170) | |

|

Fuel consumption (Nm3/h) |

natural gas | 8.5 | 17 | 25.5 | 42.5 | 56 | 70.3 |

| diesel | 6.4 | 12.8 | 19.2 | 32 | 49.5 | 64.6 | |

| lpg | 3.1 | 6.2 | 9.3 | 15.5 | 22 | 28 | |

| Note: Standard boiler parameter is for your reference, should follow the actual technical data according customer needs & engineer design. | |||||||

| Model |

Rated thermal power (kw) |

Thermal efficiency (%) |

Rated output water temperature (℃) |

Rated return water temperature (℃) |

Fuel consumption | |

| Light diesel oil(kg/h) | Natural gas(Nm3/h) | |||||

| CLHS 0.12-85/65-Y(Q) | 120 | >91 | 85 | 65 | 10 | 12 |

| CLHS 0.35-85/65-Y(Q) | 350 | >91 | 85 | 65 | 32 | 38 |

| CLHS 0.5-85/65-Y(Q) | 500 | >91 | 85 | 65 | 45 | 54 |

| CLHS 0.6-85/65-Y(Q) | 600 | >91 | 85 | 65 | 56 | 68 |

| CLHS 0.7-85/65-Y(Q) | 700 | >91 | 85 | 65 | 65 | 79 |

| Note: Standard boiler parameter is for your reference, should follow the actual technical data according customer needs & engineer design. | ||||||

Relate Cases

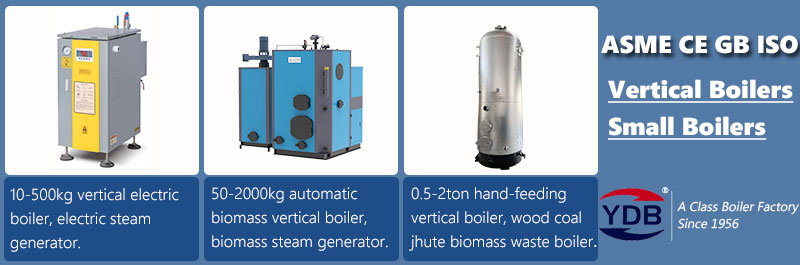

Recommend Boiler

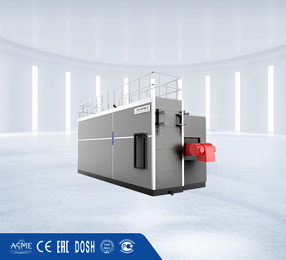

WNS Fire Tube Gas Boiler

Horizontal oil gas fired fire tube boiler, fully automatic, 3-pass wet back design

SZS Water Tube Gas Oil Boiler

Horizontal oil gas fired water tube boiler, full membrane wall boiler, seamless

LSS Once Through Boiler

100-2000kg vertical water tube boiler, small footprint, low cost, quick into use

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler