Hot oil boiler | Heat carrier boiler | Oil heating boiler

YLW series wood/biomass fired thermal oil boiler is horizontal grate combustion three-coil structure, wet back boiler. This boilers are fully automatic, energy saving and designed to operate on wide range of solid fuels, like coal, wood, husk, sawdust, multiple fuel options.

| Thermal Capacity: | 200-14,000kw/h 200,000-12,000,000Kcal/h |

| Rated Temperature: | 200 ℃ ~ 320 ℃ |

| Styles: | horizontal / vertical |

| Available Fuel: | coal, solid fuels, wood chip, bagasse, straw, and other biomass fuel |

| Applied Industries: | wood industry, refinery&chemical, plastic and rubber, textile printing and dyeing, building material, machinery industry, food industry, etc. |

Introduction

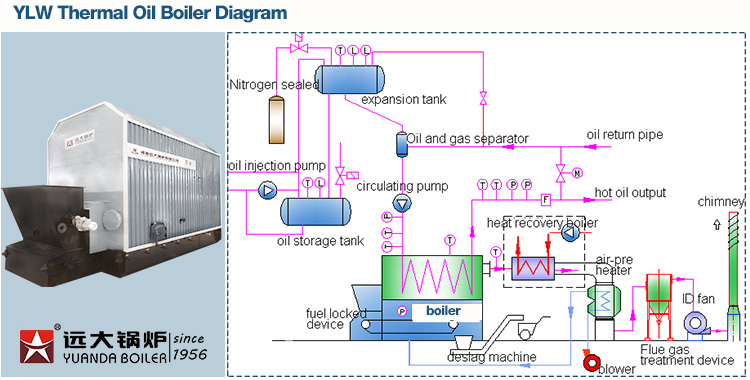

-- YLW biomass thermal fluid boiler is a heating equipment used for factory heating/drying. Providing stable and precise high temperatures (up to 350°C) at low pressure. Thermal oil/edible oil heated up inside the boiler tubes and then transfers the heat to the machine that requires heat, repeating the cycle.

-- Available in two types: horizontal biomass thermal oil boiler and vertical biomass thermal oil boiler. Thermal capacity meets 20,0000 Kcal~20m Kcal / 120kw~21,000kw.

Advantages

-- Equipped protection devices such as circulation oil pumps/thermal oil flow meters to deal with emergencies such as power outages

-- Strong fuel adaptability like biomass, log, firewood, woodchip, woodpellet, and wood waste other fuel...

-- Using energy-saving device like economizer/preheater/cyclon/wet scrubber, environmental protection and energy conservation

-- Design the feeding method & furnace layout according to client needs to ensure sufficient output and good operation of the boiler.

Product Features

● "Three Layers Coil Tubes + 3-Pass Design"Effectively use the high temperature, smoke stay inside of boiler to heat thermal oil 3 times, greatly reduce temperature of outlet smoke, improve boiler thermal efficiency, energy saving, reduce fuel cost

● "Oil Covered Fire" endothermic sufficient, heating up fast and evenly;Smoke transfer room is wet back structure, avoid burning deformation, ensure boiler lifespan

● "Patented Serpentine Tube Design + Biomass Soot Blower + Double Inspection Door" Convenient for inspection and scoot blowing, improve heat transfer rate

● Double layer 12cm aluminum silicate insulation cotton, reduce heat loss, boiler surface temperature is not higher than 40 ℃

● 100% safety with 5 Levels Interlock Control. Super oil temperature alarm, Low oil flow alarm, Over exaust temperature

● Equipped protection devices such as circulation oil pumps/thermal oil flow meters to deal with emergencies such as power outages

● Using energy-saving device like economizer/preheater/cyclon/wet scrubber, environmental protection and energy conservation

About Our Company

■ Established in 1956, as a stated owned enterprise.

■ Over 16 years export experiences, payment & shipping protection

■ CE ASME DOSH EAC GOST ISO high standard boiler certified

■ Production of various types boilers

■ Directly factory low price & quality protection.

■ Completed technology & after-sale service team.

Service

From boiler solution, optimization to installation, 24 hours online, provide technical support and avoid risks for you

Based on user needs, we supply tailored service, boiler drawing&PID system, boiler room design, foundation drawings etc

Full-life After sale service. With our professional technical experts and service team, skilled technology provides customers with professional services

According to the customer production requirements, provide professional boiler solutions, cost analysis, project investment budget, boiler drawing&installation and commissioning service

Parameter

| Model |

Rated thermal power (MW) |

Rated working pressure (Mpa) |

Thermal oil outlet temperature (℃) |

Thermal oil inlet temperature (℃) |

Fuel consumption (KG/H) |

Fuel |

| YLW-700 | 0.7 | 0.8/1.0 | 280/320 | 250/290 | 187 | Soft coal, firewood, rice husk, palm shell and the other biomass fuels |

| YLW-1400 | 1.4 | 0.8/1.0 | 280/320 | 250/290 | 373 | |

| YLW-2400 | 2.4 | 0.8/1.0 | 280/320 | 250/290 | 621.3 | |

| YLW-2900 | 2.9 | 0.8/1.0 | 280/320 | 250/290 | 756 | |

| YLW-4200 | 4.2 | 0.8/1.0 | 280/320 | 250/290 | 989.32 | |

| YLW-5600 | 5.6 | 0.8/1.0 | 280/320 | 250/290 | 1196 | |

| YLW-7000 | 7.0 | 0.8/1.0 | 280/320 | 250/290 | 1657.43 | |

| YLW-8400 | 8.4 | 0.8/1.0 | 280/320 | 250/290 | 1926.2 | |

| YLW-10500 | 10.5 | 0.8/1.0 | 280/320 | 250/290 | 2442.6 | |

| YLW-14000 | 14 | 0.8/1.0 | 280/320 | 250/290 | 3230 | |

| Note: Standard boiler parameter is for your reference, should follow the actual technical data according customer needs & engineer design. | ||||||

Relate Cases

Recommend Boiler

YGL Oil Heater

Vertical coal/biomass thermal oil heater, Small footprint, low cost, quick into use

YY(Q)W Thermal Oil Boiler

Horizontal oil gas fired hot oil heater boiler, fully automatic, low pressure with stable heating

YLW Hot Oil Boiler

Horizontal coal bioamass fired heating oil boiler, grate stoker, running stable

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler