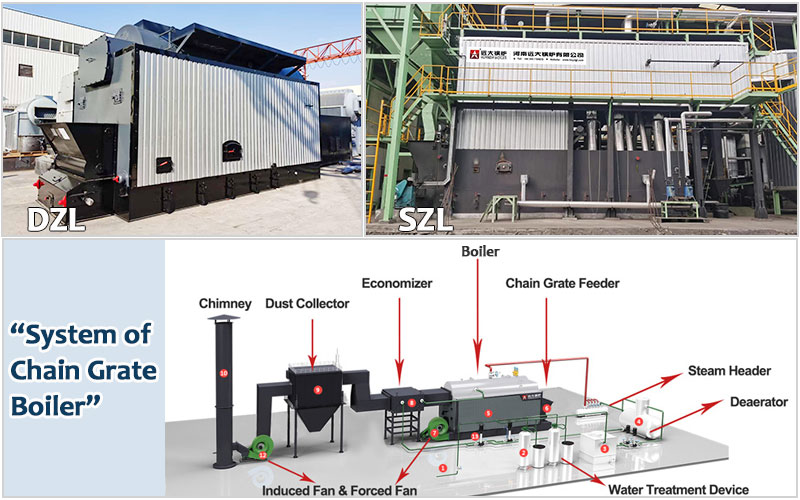

DZL SZL boiler | coal biomass boiler | automatic boiler

Chain grate boiler is a fully automatic coal/biomass fired boiler, can produce steam/hot water as transfer medium, grate combustion, adopts water&fire tube structure, high steam quality, anti coking, and sufficient output, etc.

| Fuel: | coal, biomass pellet, wood chips, palm shell, rice husk, waste wood etc |

| Capacity: | 100kg-50000kg, 0.1ton-50ton, 120kw-28000kw |

| Work Pressure: | 3-40bar, 0.3-4.0Mpa |

| Output: | steam, hot water |

| Applied Industry: | For heating/drying/turbine drive, in food, beverage, paper plant, textile mill, feed mill, pharm, package, chemical, building materials, laundry etc |

Introduction

Yuanda boiler has DZL chain grate boiler and SZL chain grate boiler. Can produce steam or hot water for factory production, building heating, or turbine drive.

Both boilers using moving chain grate (small flake type is optional). With advantages of mechanized automatic feeding, strong fuel adaptability, steady running, less coal leakage, and easy maintenance.

Fuel can be coal, biomass/wood pellet, wood chips, rice husk, palm kernel shells, fruit shells etc.

1. 3-pass wet back sructure, arched tube plate, to strengthen boiler efficiency;

2. New furnace arch with upside down "α" flue gas flow;

3. Equipped economizer/preheater/cyclon/wet scrubber, environmental protection and energy conservation;

4. Built-in steam separator, ensure high steam quality with wetness below 1%;

5. Five stages safety features like water level, pressure and temperature monitoring etc;

6. Built-in dust cleaning system, and inspection door;

7. Dust separation chamber, higher efficiency, reduce the original dust;

8. PLC control, interlock system for fuel feeding, water treatment, combustion furnace, fan.

Quality Assurance

Steel element test→Steel rust cleaning→Welding electrodes drying process→Automatic welding, argon arc welding, expansion welding etc. methods→NDT(Nondestructive Testing) including X-ray Test, Ultrasonic Test, Magnetic particle Test→Hydraulic pressure test.

Boiler Service

Pre-sale Service:

1. Design一We help customer to choose the best boiler model according to the different requirements of different industries.

2. Drawing and files一Supply quality certificates, factory-inspect, fuel consumption calculation, cost analysis, foundation drawings, layout drawings, boiler room drawings nased on your needs, etc.

3. Technical Solution一Design completed boiler solution with installation materials for your company.

4. Transportation一We have shipping partners and forwarder for lowest price and safe.

After-sale Service:

1. Provide a full range of boiler and original spare parts.

2. Overseas engineers installation and commissioning service is available.

3. Training in site, to ensure safe operation.

4. 24 hours online, quick respond.

5. Free maintenance and repair for one year and lifetime service.

Parameter

| Model |

Rated steam output (Ton/hr) |

Rated steam pressure (Mpa) |

Rated steam temperature (℃) |

Feed water temperature (℃) |

Thermal efficiency (%) |

Fuel consumption (Kg/h) |

| DZL 1-0.7/1.0/1.25/1.6-AII | 1 | 0.4 to 2.5 (4-25 in bar) | 130~226 | 20/105 | >84 | 140 |

| DZL 2-0.7/1.0/1.25/1.6-AII | 2 | 0.4 to 2.5 (4-25 in bar) | 130~226 | 20/105 | >84 | 280 |

| DZL 4-0.7/1.0/1.25/1.6-AII | 4 | 0.4 to 2.5 (4-25 in bar) | 130~226 | 20/105 | >84 | 570 |

| DZL 6-0.7/1.0/1.25/1.6-AII | 6 | 0.4 to 2.5 (4-25 in bar) | 130~226 | 20/105 | >84 | 810 |

| DZL 8-0.7/1.0/1.25/1.6-AII | 8 | 0.4 to 2.5 (4-25 in bar) | 130~226 | 20/105 | >84 | 1100 |

| DZL 10-0.7/1.0/1.25/1.6-AII | 10 | 0.4 to 2.5 (4-25 in bar) | 130~226 | 20/105 | >84 | 1380 |

| DZL 15-0.7/1.0/1.25/1.6-AII | 15 | 0.4 to 2.5 (4-25 in bar) | 130~226 | 20/105 | >84 | 2100 |

| DZL 20-0.7/1.0/1.25/1.6-AII | 20 | 0.4 to 2.5 (4-25 in bar) | 130~226 | 20/105 | >84 | 2600 |

| Note: Standard boiler parameter is for your reference, should follow the actual technical data according customer needs & engineer design. | ||||||

| Model |

Rated thermal power (MW) |

Rated working pressure (Mpa) |

Rated output water temperature (℃) |

Rated return water temperature (℃) |

Thermal efficiency (%) |

Fuel consumption (Kg/h) |

| DZL 0.7-0.7/1.0-AII | 0.7 | 0.7/1.0 (7-10 in bar) | 95/115 | 70 | >84 | 150 |

| DZL 1.4-0.7/1.0-AII | 1.4 | 0.7/1.0 (7-10 in bar) | 95/115 | 70 | >84 | 302 |

| DZL 2.8-0.7/1.0-AII | 2.8 | 0.7/1.0 (7-10 in bar) | 95/115 | 70 | >84 | 596 |

| DZL 4.2-0.7/1.0-AII | 4.2 | 0.7/1.0 (7-10 in bar) | 95/115 | 70 | >84 | 880 |

| DZL 5.6-0.7/1.0-AII | 5.6 | 0.7/1.0 (7-10 in bar) | 95/115 | 70 | >84 | 1160 |

| DZL 7-0.7/1.0-AII | 7.0 | 0.7/1.0 (7-10 in bar) | 95/115 | 70 | >84 | 1380 |

| DZL 10.5-0.7/1.0-AII | 10.5 | 0.7/1.0 (7-10 in bar) | 95/115 | 70 | >84 | 2030 |

| DZL 14-0.7/1.0-AII | 14 | 0.7/1.0 (7-10 in bar) | 95/115 | 70 | >84 | 2700 |

| Note: Standard boiler parameter is for your reference, should follow the actual technical data according customer needs & engineer design. | ||||||

Relate Cases

Recommend Boiler

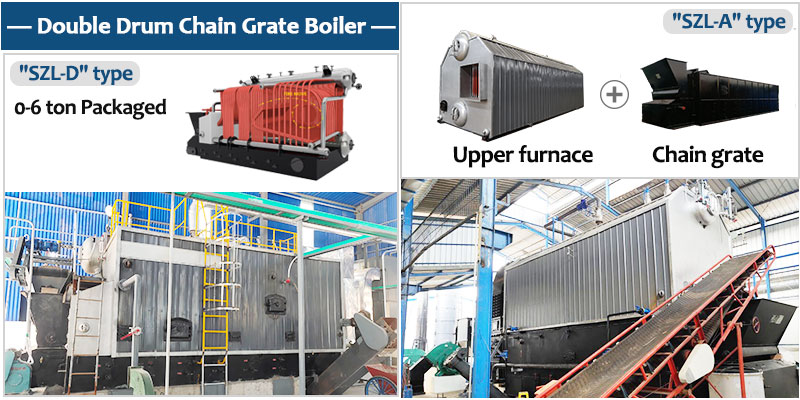

SZL Chain Grate Boiler

2-30ton/h double drum grate combustion boiler. Fully automatic, suitable for multiple biomass, like pellets, palm shell etc

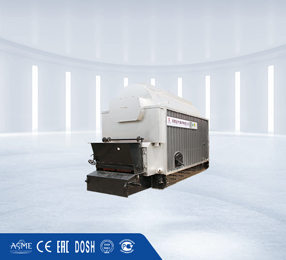

DZH Coal/Wood Boiler

1-8ton/h traveling grate boiler, hand feeding way, running stable, suitable for bigger fuel like wood log

LSG Vertical Coal Boiler

0.3-1ton/h fixed grate boiler, hand feeding way. Small footprint, quick into use, low cost, run stable

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler