Fast steam/hotwater generation | Watertube steam generator

LSS high-speed steam/hot water generator with a top-mounted burner and water tube design, achieving 97%+ dry saturated steam in under 5 minutes from cold start. Minimizes carryover and reduces fuel consumption for energy-efficient operation.

| Output: | steam, hot water |

| Capacity: | 100-1000kg 120-700kw 0.1-1ton |

| Horsepower | 10-70hp boiler |

| Fuel: | natural gas, lpg, biogas, diesel, heavy oil, propane, dual fuel |

| Application: | food, beverage, diary, milk, feed mill, refinery, chemical, slaughterhouse, laundry, hotel, greenhouse, etc |

Introduction

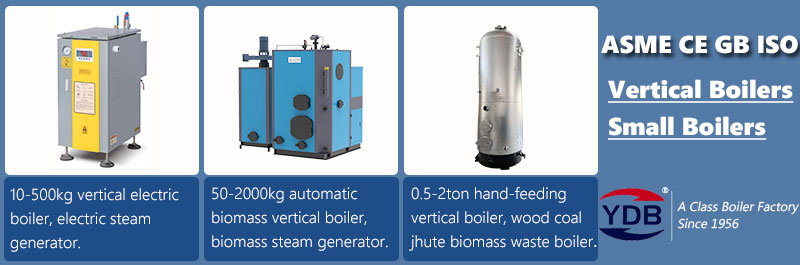

Yuanda Boiler offers premium gas or oil fuel fired steam generator (steam boiler), capacity from 0.1ton to 20ton.

Including WNS horizntal steam generator, portable steam generator, LHS vertical fire tube steam generator and LSS once through steam generator, water tube steam generator.

Steam Generator Size: We have 100Kg/h, 150Kg/h, 200Kg/h, 300Kg/h, 500Kg/h, 750Kg/h, 1000Kg/h ... For bigger size above 1000Kg/h , please consider our "WNS" horizontal type.

It can be used in a variety of industries such as food, beverage, milk, garment, pharmaceutical, building materials, chemicals, textile, paper, foam, feed mills, edible oils, starch, dairy products, food, wood processing, EPS, leather, battery, soap, refineries, rubber, packaging, laundry, hotel, slaughthouse, greenhouse...

WNS horizontal steam generator is a fully automatic, horizontal gas/oil-fired boiler. It adopts three-pass fire tube wet-back structure, large corugated furmace and thread smoke tube technology, finned tube economizer, equipped with intemational first-level brand burners, valves, instruments, advanced expansion welding technique. Independently developed high-matching PLC control system to realize muitiple linkages, protects the boiler long uselife & safety running.

✔ Compact design saves space and costs – Smaller footprint, radiation losses and larger fuel savings

✔ Faster steam production = reduced downtime – No more waiting for steam.

✔ Energy-efficient operation – Cuts fuel use, saving you money long-term.

✔ Reliable, high-quality steam – Dry, saturated steam (97%+) for consistent performance.

✔ Eco-friendly – Optimized combustion reduces waste and resource consumption.

Why believe Yuanda boiler quality?

(1) Strength calculation report with applied materials information;

(2) 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3) 100% X-ray inspection( (Longitudinal, transversal safety inspection)): ensure the quality of entire boiler;

(4) Hydrostatic test: ensure the standard working pressure and safety;

(5) Third-party inspection report

(6) Passed ASME CE ISO DOSH EAC GOST boiler level certificate.

Our Service

Pre-sale Service:

1. Design一We help customer to choose the best boiler model according to the different requirements of different industries.

2. Drawing and files一Supply quality certificates, factory-inspect, fuel consumption calculation, cost analysis, foundation drawings, layout drawings, boiler room drawings nased on your needs, etc.

3. Technical Solution一Design completed boiler solution with installation materials for your company.

4. Competitive Price一As one boiler factory, we have lowest price and high quality.

After-sale Service:

1. Provide a full range of boiler and original spare parts.

2. Overseas engineers installation and commissioning service is available.

3. Training in site, to ensure safe operation.

4. 24 hours online, quick respond.

5. Free maintenance and repair for one year and lifetime service.

Parameter

| Model | Horsepower | Rated steam output | Rated pressure | Rated temperature | Feed water temperature | Fuel consumption | |

| (hp) | (Ton/hr) | (Mpa) | (℃) | (℃) | Light diesel oil(kg/h) | Natural gas(Nm3/h) | |

| LSS0.1 | 7hp | 0.1 | 0.4/0.7 mpa | 130~171 | 20/105 | 6.7 | 7.3 |

| LSS0.2 | 15hp | 0.2 | 130~171 | 20/105 | 12.8 | 17 | |

| LSS0.3 | 25hp | 0.3 | 130~171 | 20/105 | 19.2 | 25.5 | |

| LHS0.5/LSS0.5/WNS0.5 | 35hp | 0.5 | 130~171 | 20/105 | 32 | 42.5 | |

| LHS0.7/WNS0.7 | 50hp | 0.7 | 130~171 | 20/105 | 49.5 | 51 | |

| LHS1/WNS1 | 65hp | 1.0 | 0.4/0.7/1.0/1.25/1.6/2.5/3.0 mpa | 130~185 | 20/105 | 70 | 80 |

| LHS1.5/WNS1.5 | 100hp | 1.5 | 130~185 | 20/105 | 108.7 | 115.4 | |

| LHS2/WNS2 | 125hp | 2 | 130~185 | 20/105 | 135.2 | 150.4 | |

| WNS3 | 200hp | 3 | 130~226 | 20/105 | 192.9 | 212.1 | |

| WNS4 | 250hp | 4 | 130~226 | 20/105 | 258.2 | 283.4 | |

| WNS5 | 300hp | 5 | 130~226 | 20/105 | 323.5 | 354.7 | |

| WNS6 | 350hp | 6 | 130~226 | 20/105 | 388.6 | 424.2 | |

| WNS8 | 500hp | 8 | 130~226 | 20/105 | 514.6 | 566.3 | |

| WNS10 | 600hp | 10 | 130~226 | 20/105 | 641.7 | 707.8 | |

| WNS12 | 720hp | 12 | 130~226 | 20/105 | 768.9 | 849.3 | |

| WNS15 | 900hp | 15 | 130~226 | 20/105 | 960.1 | 1061.7 | |

| WNS20 | 1200hp | 20 | 130~226 | 20/105 | 1276.2 | 1415.8 | |

| Model |

Rated thermal power (kw) |

Thermal efficiency (%) |

Rated output water temperature (℃) |

Rated return water temperature (℃) |

Fuel consumption | |

| Light diesel oil(kg/h) | Natural gas(Nm3/h) | |||||

| CLSS 0.12-85/65-Y(Q) | 120 | >91 | 85 | 65 | 10 | 12 |

| CLSS 0.35-85/65-Y(Q) | 350 | >91 | 85 | 65 | 32 | 38 |

| CLSS 0.5-85/65-Y(Q) | 500 | >91 | 85 | 65 | 45 | 54 |

| CLSS 0.6-85/65-Y(Q) | 600 | >91 | 85 | 65 | 56 | 68 |

| CLSS 0.7-85/65-Y(Q) | 700 | >91 | 85 | 65 | 65 | 79 |

| Note: Standard boiler parameter is for your reference, should follow the actual technical data according customer needs & engineer design. | ||||||

Relate Cases

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler