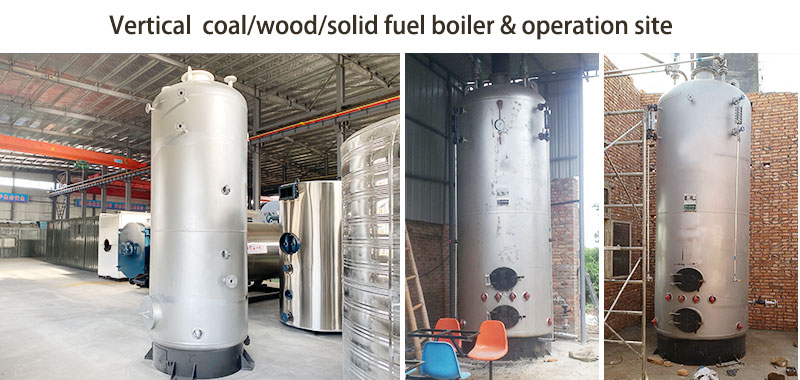

Vertical coal boiler | Small vertical boiler | Vertical grate boiler

The boiler is vertical type small capacity boiler, compare with older boiler, temperature rise up faster, save energy, and higher thermal efficiency. Compact structure, convenient installation and migration, small footprint and low investment

| Output: | steam |

| Thermal Capacity: | 100-1,000kg |

| Styles: | vertical |

| Available Fuel: | coal, wood log, firewood, jute, solid fuel etc |

| Applied Industries: | food, beverage, diaries, feed mill, garment, textile mill, paper mill, packaged, refinery, chemical, laundry, hotel, greenhouse etc |

| Pressure | 0.4/0.7/1.0 Mpa |

Introduction

Vertical solid fuel boiler capacity 200kg-1000kg.

This vertical boiler widely used for food and beverage, dairy, garment, canteen, washing and ironing industry, packaging and labeling industry, sauna, heat exchange equipment, slaughthouse, hotel, laundry, and so on etc;

LSG series vertical coalor wood biomass boiler is a safe&low cost heating equipment with stable running, compact structure, reduce construction cost.

Vertical coal/wood boiler adopts “water tube stucturer". It has compact structure, easy to install, small footprint, small investment; Multi-pass and multi-return, the dust can be removed naturally without ID fan, save energy; High quality, running stable and loong life span; It is easy to operate and maintain, small in size and low in capital investment, more economical boiler options for scale factory.

Characteristics

01

Packaged compact structure & Small footprint

1. Quick into use, only need connect oil/gas, fee water, electric power; 2. Adopts vertical structure, occupy small area, no need boiler room, reduce cost.

02

PLC control system, high degree of automation

Two sets of safety spare parts, high and low water level alarm and low water level interlock protection, steam overpressure alarm and interlock protection function

03

ND Economizer Design, Energy Saving

Recycle exhausted smoke to heat feed water, reduce exhaust smoke temperature, increase feed water temp then save fuel cost at least 6-10% per hour

Benefits

From boiler solution, optimization to installation, 24 hours online, provide technical support and avoid risks for you

Based on user needs, we supply tailored service, boiler drawing&PID system, boiler room design, foundation drawings etc

Full-life After sale service. With our professional technical experts and service team, skilled technology provides customers with professional services

According to the customer production requirements, provide professional boiler solutions, cost analysis, project investment budget, boiler drawing&installation and commissioning service

Parameter

| Model |

Rated steam output (Ton/hr) |

Rated steam pressure (Mpa) |

Rated steam temperature (℃) |

Feed water temperature (℃) |

Thermal efficiency(%) | Overall dimension (m) |

| LSG0.1-0.4-AⅡ/T | 0.1 | 0.4/0.7(4-10 in bar) | 130~174 | 20 | 89 | 0.8x 1.94 |

| LSG0.2-0.4-AⅡ/T | 0.2 | 0.4/0.7(4-10 in bar) | 130~174 | 20 | 89.2 | 0.9x 2.7 |

| LSG0.3-0.4/0.7-AⅡ/T | 0.3 | 0.4/0.7(4-10 in bar) | 130~174 | 20 | 89.5 | 1.2x 2.58 |

| LSG0.5-0.4/0.7-AⅡ/T | 0.5 | 0.4/0.7(4-10 in bar) | 130~174 | 20 | 89.6 | 1.3x 2.95 |

| LSG0.7-0.4/0.7-AⅡ/T | 0.7 | 0.4/0.7(4-10 in bar) | 130~174 | 20 | 91 | 1.6x 3.0 |

| LSG1-0.4/0.7-AⅡ/T | 1 | 0.4/0.7(4-10 in bar) | 130~174 | 20 | 91 | 1.5x 3.2 |

| Note: Standard boiler parameter is for your reference, should follow the actual technical data according customer needs & engineer design. | ||||||

Relate Cases

Recommend Boiler

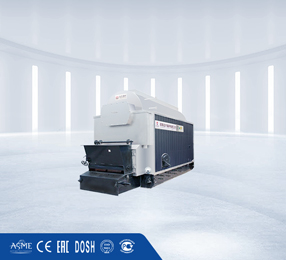

DZL Biomass boiler

Single drum chain grate burning solid fuel boiler, water&fire tube boiler, fully automatic

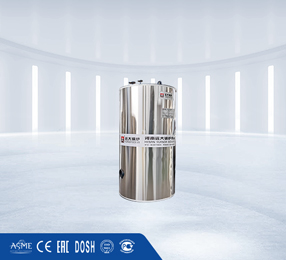

LHS Oil Gas Boiler

Vertical oil gas fired boiler, 100-2000kg, quick into use, high efficiency & energy saving

WNS Oil Gas Fired Boiler

Horizontal 3-pass fire tube boiler with famous burner. Energy saving

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler