gas burner boiler | industrial steam boiler | gas fired hot water boiler

WNS series gas-fired boiler is a three-pass wet-back boiler, which can generate steam or hot water for factory use. Fully automatic operation, safety and energy saving. Equipped with well-known burners, it is suitable for various liquid and gaseous fuels, such as lpg, natural gas or dual fuel.

| Output: | steam, hot water |

| Capacity: | 0.1ton-40ton, 80-14000kw. |

| Styles: | horizontal |

| Available Fuel: | natural gas, biogas, LNG, LPG, dual fuel etc |

| Applied Industries: | food, beverage, diary, feed mill, garment, textile, chemical, paper, packaged, refinery, chemical, laundry, hotel, greenhouse etc |

Introduction

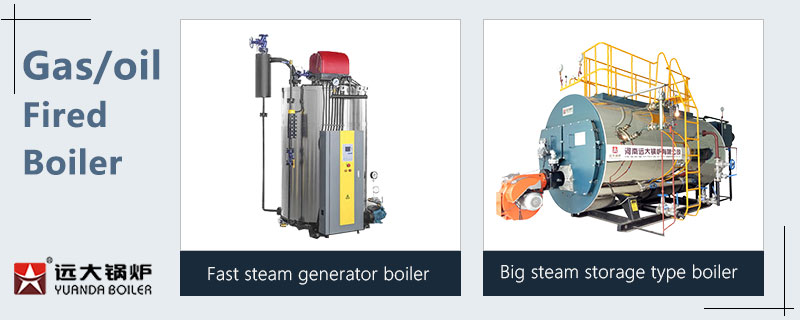

Yuanda has LSS water tube gas oil steam generator and WNS fire tube gas oil boiler. Can produce saturated steam, superheated steam and hot water for factory production.

Type A:LSS fast steam generation boiler with a top-mounted burner and water tube design, achieving 97%+ dry saturated steam in under 5 minutes from cold start. Minimizes carryover and reduces fuel consumption for energy-efficient operation.

Type B:WNS horizontal gas and oil fired boiler is package type three pass fire tube boiler, produce hot water, saturated steam or superheated steam. The boiler has a larger corrugated furnace which have big radiate heating area, and adopted threaded smoke tube, finned tube economizer which greatly increased the boiler heat transfer efficiency. Independently developed PLC control system to realize multiple linkage.

Steam/Hotwater Boiler Size

We have 100Kg/h, 150Kg/h, 200Kg/h, 300Kg/h, 500Kg/h, 750Kg/h, 1000Kg/h, 2000Kg/h...up to 20000Kg/h. For bigger size above 500Kg/h , Please choose our "WNS" type horizontal boiler. Sufficient output and high steam quality with wetness below 1%. For smaller size below 500Kg , please choose our "LSS" type vertical boiler, compact design saves space and costs.

✔ Compact design saves space and costs – Smaller footprint, radiation losses and larger fuel savings

✔ Faster steam production = reduced downtime – No more waiting for steam.

✔ Energy-efficient operation – Cuts fuel use, saving you money long-term.

✔ Reliable, high-quality steam – Dry, saturated steam (97%+) for consistent performance.

✔ Eco-friendly – Optimized combustion reduces waste and resource consumption.

Ideal for: Industrial processes, food/beverage, manufacturing, and any operation needing fast, efficient steam or hot water on demand.

●High Efficiency, Save Fuel & Running Cost;

①Large corrugated furnace, patent design three pass smoke tubes;

②Built-in steam separator, ensure high steam quality with wetness below 1%;

③Double 12mm thickness aluminum silicate insulation layer;

④Finned tube design economizer with aluminum silicate insulation, greatly reducing heat loss.

●High Security, Safe Operation;

①PLC Control ensures automatic water feeding, low water protection and alarm, extremely low water emergency stop, pressure protection, safety valve pressure relief, etc.

②The LCD touch screen shows the working condition of burner, feed water pump, steam pressure, steam flow and steam temperature

●Long Using Life and Easy for Maintenance

①Wet-back reverse flame chamber;

②Solid round steel tension rod design;

③Rapid solidification and high-strength refractory building materials;

④Double opening-door at front and back.

1. Spare parts available at ex-factory price

2. Different voltage available

3. 100% tested before delivery

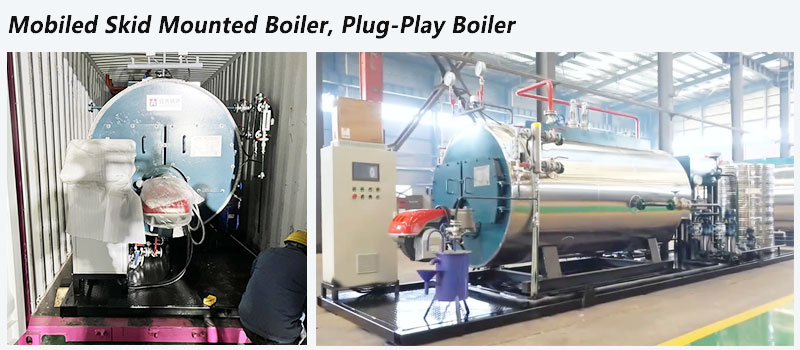

4. Skid-mounted steam boiler system available5. Container type steam boiler system available

Why believe Yuanda boiler quality?

(1) Strength calculation report with applied materials information;

(2) 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3) 100% X-ray inspection( (Longitudinal, transversal safety inspection)): ensure the quality of entire boiler;

(4) Hydrostatic test: ensure the standard working pressure and safety;

(5) Third-party inspection report

(6) Passed ASME CE ISO DOSH EAC GOST boiler level certificate.

Our Service

Pre-sale Service:

1. Design一We help customer to choose the best boiler model according to the different requirements of different industries.

2. Drawing and files一Supply quality certificates, factory-inspect, fuel consumption calculation, cost analysis, foundation drawings, layout drawings, boiler room drawings nased on your needs, etc.

3. Technical Solution一Design completed boiler solution with installation materials for your company.

4. Competitive Price一As one boiler factory, we have lowest price and high quality.

After-sale Service:

1. Provide a full range of boiler and original spare parts.

2. Overseas engineers installation and commissioning service is available.

3. Training in site, to ensure safe operation.

4. 24 hours online, quick respond.

5. Free maintenance and repair for one year and lifetime service.

Parameter

| Model | Horsepower | Rated steam output | Rated pressure | Rated temperature | Feed water temperature | Fuel consumption | |

| (hp) | (Ton/hr) | (Mpa) | (℃) | (℃) | Light diesel oil(kg/h) | Natural gas(Nm3/h) | |

| LSS0.1 | 7hp | 0.1 | 0.4/0.7 mpa | 130~171 | 20/105 | 6.7 | 7.3 |

| LSS0.2 | 15hp | 0.2 | 130~171 | 20/105 | 12.8 | 17 | |

| LSS0.3 | 25hp | 0.3 | 130~171 | 20/105 | 19.2 | 25.5 | |

| LHS0.5/LSS0.5/WNS0.5 | 35hp | 0.5 | 130~171 | 20/105 | 32 | 42.5 | |

| LHS0.7/WNS0.7 | 50hp | 0.7 | 130~171 | 20/105 | 49.5 | 51 | |

| LHS1/WNS1 | 65hp | 1.0 | 0.4/0.7/1.0/1.25/1.6/2.5/3.0 mpa | 130~185 | 20/105 | 70 | 80 |

| LHS1.5/WNS1.5 | 100hp | 1.5 | 130~185 | 20/105 | 108.7 | 115.4 | |

| LHS2/WNS2 | 125hp | 2 | 130~185 | 20/105 | 135.2 | 150.4 | |

| WNS3 | 200hp | 3 | 130~226 | 20/105 | 192.9 | 212.1 | |

| WNS4 | 250hp | 4 | 130~226 | 20/105 | 258.2 | 283.4 | |

| WNS5 | 300hp | 5 | 130~226 | 20/105 | 323.5 | 354.7 | |

| WNS6 | 350hp | 6 | 130~226 | 20/105 | 388.6 | 424.2 | |

| WNS8 | 500hp | 8 | 130~226 | 20/105 | 514.6 | 566.3 | |

| WNS10 | 600hp | 10 | 130~226 | 20/105 | 641.7 | 707.8 | |

| WNS12 | 720hp | 12 | 130~226 | 20/105 | 768.9 | 849.3 | |

| WNS15 | 900hp | 15 | 130~226 | 20/105 | 960.1 | 1061.7 | |

| WNS20 | 1200hp | 20 | 130~226 | 20/105 | 1276.2 | 1415.8 | |

| Model |

Rated heating capacity (mw) |

Rated working pressure (Mpa) |

Output water temperature (℃) |

Return water temperature (℃) |

Fuel consumption | |

| Light diesel oil(kg/h) | Natural gas(Nm3/h) | |||||

| WNS 0.35 | 0.35mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 31.6 | 36.6 |

| WNS 0.7 | 0.7mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 60.4 | 69.3 |

| WNS 1.4 | 1.4mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 122.8 | 146.1 |

| WNS 2.1 | 2.1mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 192.3 | 227.1 |

| WNS 2.8 | 2.8mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 246.1 | 286.5 |

| WNS 4.2 | 4.2mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 367.1 | 412.6 |

| WNS 5.6 | 5.6mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 490.2 | 543.7 |

| WNS 7.0 | 7.0mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 593.6 | 660.7 |

| WNS 10.5 | 10.5mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 936.5 | 998.8 |

| WNS 14 | 14mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 1200.8 | 1330.7 |

| Note: for place limited, we didn't list all models, if you need other capacity, pressure, fuel, please send us inquiry directly, we will send you detailed parameter. | ||||||

Relate Cases

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler