Gas/diesel steam generator | Electric steam generator | Waste heat steam generator

Industrial steam generator, water tube steam generator, fire tube steam generator, gas fired steam genrator, oil fired steam generator, coal steam generator, biomass wood steam generator, electric steam generator, stainless steel steam generator, waste heat steam genertor.

| Output: | steam |

| Thermal Capacity: | 0.1 - 50ton/h, 80 - 28000kw |

| Horsepower: | 4 to 2500hp |

| Available Fuel: | oil, gas, coal, wood, biomass, electricity, waste gas |

| Applied Industries: | food, beverage, laundry, dairy, garment, textile, palm oil, concrete, medical, paper, building materials, hotel etc |

Introduction

Steam generator is used to produce saturated(or superheated) steam for heating/drying/sterilization/cleaning purpose etc. We have 4 kind steam generator powered by different fuel:

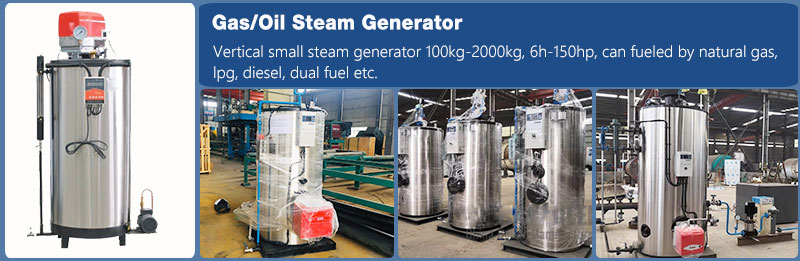

① Gas/oil steam generator (horizontal & vertical type)

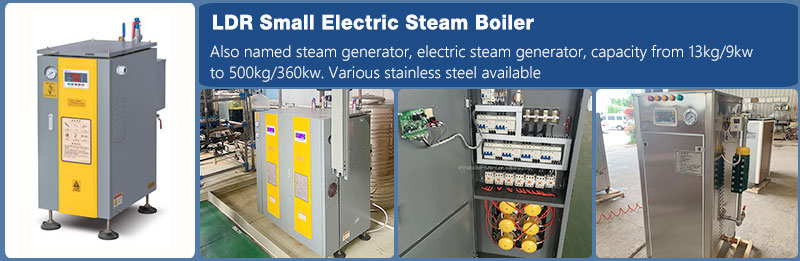

② Electric steam generator (basic & clean type)

③ Biomass/wood steam generator (compact type)

④ Waste heat steam generator (customized type)

It is also called green steam generator, pure steam generator, stainless steel steam generator. Small scale, high quality steam quality and fast heat up. One key to start, movable boiler, competitive type, easy to install and use. Steam capacity from 100kg to 500kg/h.

CWHS biomass/wood pellet boiler has strong fuel adaptability, automatic feeding, compact structure and can provide steam and hot water at the same time.

Customized waste heat boilers efficiently utilize exhaust gas to generate steam. Typically used in conjunction with gas generator sets and lithium bromide plants.

Yuanda's philosophy: "Quality First, Integrity Wins the World, and Common Development with Customers"

Company Strength

■ Founded in 1956, a premium supplier assessed, certified, and inspected by SGS Group. Leading industrial boiler manufacturer in China.■ Products sold to over 130 countries/regions, covering food, beverage, textiles, paper, wood industries. Serving over 100,000 customers.

Products & Technology

■ Diverse Product Range: Fire-tube boilers, water-tube boilers, water-fire-tube boilers, combined boilers, vertical boilers, cogeneration boilers, waste heat recovery boilers, skid-mounted boilers, and mobile containerized boilers.■ Collaboration with advanced boiler research institutes ensures advanced technology and high energy efficiency.

Services & Markets

■ Local Support: We have long-term, reliable local agents, can provide one-stop service from installation and training to maintenance.■ High Repurchase Rate: 55% of our customers are repeat customers or referral customers.

Quality Assurance

(1) Strength calculation report with applied materials information;

(2) 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3) 100% X-ray inspection( (Longitudinal, transversal safety inspection)): ensure the quality of entire boiler;

(4) Hydrostatic test: ensure the standard working pressure and safety;

(5) Third-party inspection report

Service

Parameter

| Model | Rated capacity | Input power | Rated pressure | Steam temperature | Thermal efficiency | Dimension | Weight |

| Unit | kg/h | kw | Mpa | ºC | % | mm | kg |

| LDR0.013-0.7 | 13 | 9 | 0.7 | 171 | 99.9 | 650×390×750 | 70 |

| LDR0.017-0.7 | 17 | 12 | 0.7 | 171 | 99.9 | 650×390×750 | 75 |

| LDR0.025-0.7 | 25 | 18 | 0.7 | 171 | 99.9 | 750×450×1050 | 90 |

| LDR0.035-0.7 | 35 | 24 | 0.7 | 171 | 99.9 | 750×520×1050 | 95 |

| LDR0.05-0.7 | 50 | 36 | 0.7 | 171 | 99.9 | 750×580×1150 | 101 |

| LDR0.065-0.7 | 65 | 48 | 0.7 | 171 | 99.9 | 800×580× 1200 | 115 |

| LDR0.075-0.7 | 75 | 54 | 0.7 | 171 | 99.9 | 800×580× 1300 | 140 |

| LDR0.085-0.7 | 85 | 60 | 0.7 | 171 | 99.9 | 800×600× 1300 | 145 |

| LDR0.1-0.7 | 100 | 72 | 0.7 | 171 | 99.9 | 860×650× 1390 | 172 |

| LDR0.11-0.7 | 110 | 80 | 0.7 | 171 | 99.9 | 860×650× 1390 | 185 |

| LDR0.125-0.7 | 125 | 90 | 0.7 | 171 | 99.9 | 860×650× 1430 | 190 |

| LDR0.15-0.8 | 150 | 108 | 0.8 | 175 | 99.9 | 920×760×1600 | 245 |

| LDR0.18-0.8 | 180 | 126 | 0.8 | 175 | 99.9 | 920×760× 1600 | 260 |

| LDR0.2-0.8 | 200 | 144 | 0.8 | 175 | 99.9 | 1130×750× 1780 | 450 |

| LDR0.25-0.8 | 250 | 180 | 0.8 | 175 | 99.9 | 950×900× 1830 | 650 |

| LDR0.3-0.8 | 300 | 216 | 0.8 | 175 | 99.9 | 1320×1040× 1920 | 760 |

| LDR0.4-0.8 | 400 | 288 | 0.8 | 175 | 99.9 | 1380×1040× 2070 | 890 |

| LDR0.5-0.8 | 500 | 360 | 0.8 | 175 | 99.9 | 1020×890× 2350 | 1020 |

| WDR0.5-1.0 | 500 | 360 | 1 | 184 | 98 | 1755*1180*1510 | 1400 |

| WDR1.0-1.0 | 1000 | 700 | 1 | 184 | 98 | 2530*1380*1480 | 1730 |

| WDR2-1.0 | 2000 | 1400 | 1 | 184 | 98 | 2530*2000*2080 | 2730 |

| WDR3-1.25 | 3000 | 2100 | 1.25 | 194 | 98 | 2630*2210*2160 | 3420 |

| WDR4-1.25 | 4000 | 2800 | 1.25 | 194 | 98 | 3680*2360*2380 | 4320 |

| WDR5-1.25 | 5000 | 3500 | 1.25 | 194 | 98 | 3980*2580*2560 | 5130 |

Relate Cases

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler