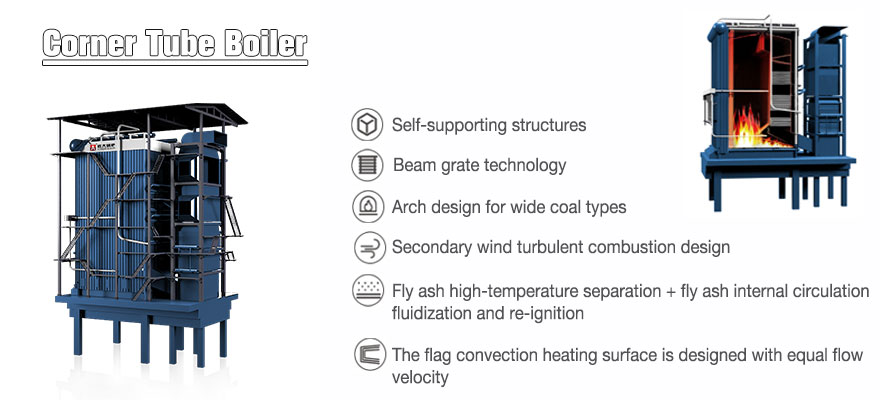

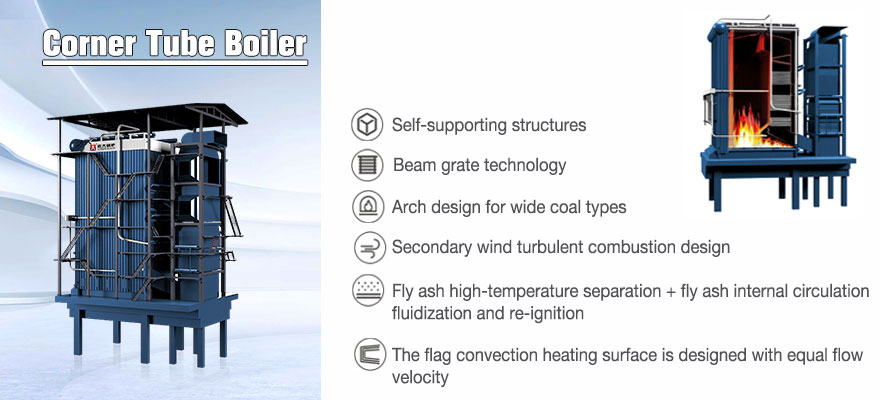

DHL DHW boiler | Multi-fuel boiler | Corner tube boiler

The DHL DHW corner tube boiler, also known as D-type boiler, capacity from 20 tons to 75 tons. Corner tube boilers are self-supporting structures that do not require additional steel supports; flexible fuel selection, suitable for co-firing of various fuels, ideal for power generation, heating, sugar refining, chemicals, food, and rubber.

| Output: | steam/hot water |

| Capacity: | 20 ton/h-75 ton/h |

| Work Pressure: | 1.25mpa to 4.0mpa |

| Available Fuel: | coal, biomass, woodchip, palm shell/fiber, EFB, rice husk, bagasse, forest waste, mixed fuel... |

| Applied Industries: | power generation, heating, chemicals, food, rubber, sugar refinery, palm oil mill... |

Introduction

Uses: power generation, heating, chemicals, food, rubber.

DHL biomass corner tube boilers offer advantages such as high thermal efficiency, low operating costs, long-term trouble-free operation, low boiler outlet dust emissions, light weight, low infrastructure investment, and direct factory sales. On-site installation requires minimal work and has a short installation period. These features make them the latest alternative to large-capacity steam boilers.

Technical Features

Company Strength

■ Founded in 1956, a premium supplier assessed, certified, and inspected by SGS Group. Leading industrial boiler manufacturer in China.

■ Holds international boiler certifications: CE, ASME, DOSH, EAC, GOST, ISO

■ Over 17 years of export experience, gold-level supplier, ensuring payment and delivery.

■ Professional team integrating R&D, production, sales, and service.

■ 53,053㎡ Factory area, supporting video/VR factory audits or third-party inspections.

■ Engineers serving over 50 countries.

■ Products sold to over 130 countries/regions, covering food, beverage, textiles, paper, wood industries. Serving over 100,000 customers.

Products & Technology

■ Diverse Product Range: Fire-tube boilers, water-tube boilers, water-fire-tube boilers, combined boilers, vertical boilers, cogeneration boilers, waste heat recovery boilers, skid-mounted boilers, and mobile containerized boilers.

■ Flexible Fuels: Supports various fuels such as natural gas, biogas, lpg, diesel, heavy oil, dual fuels, coal, biomass, wood chips, sawdust, bagasse, wood residue, sawdust, forest waste, palm shells, hybrid biomass/gas, palm fiber, rice husks, walnut shells, electricity, etc.

■ Collaboration with advanced boiler research institutes ensures advanced technology and high energy efficiency.

Services & Markets

■ Local Projects: We have installed many boiler projects in different countries, can provide boiler case studies.

■ High Repurchase Rate: 55% of our customers are repeat customers or referral customers.

■ Local Support: We have long-term, reliable local agents, can provide one-stop service from installation and training to maintenance.

■ Comprehensive Service: From project planning to after-sales support, we provide comprehensive support throughout the whole boiler life, with 24/7 online support and immediate response.

Quality Assurance

(1) Strength calculation report with applied materials information;

(2) 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3) 100% X-ray inspection( (Longitudinal, transversal safety inspection)): ensure the quality of entire boiler;

(4) Hydrostatic test: ensure the standard working pressure and safety;

(5) Third-party inspection report

(6) Passed ASME CE ISO DOSH EAC GOST boiler level certificate.

Service

Comprehensive Boiler Solutions – From Planning to Lifetime Support

Pre-Sales Support:Expert Design Guidance: Help you select the optimal boiler model tailored to your industry needs.

Detailed Technical Documentation: Provide certificates, CAD drawings, consumption analysis, and boiler room planning.

Customized Solutions: Deliver complete system designs including installation material lists.

Competitive Pricing: Factory-direct rates with uncompromised quality.

After-Sales Assurance:Genuine Spare Parts: Original components with reliable supply.

Global Installation & Commissioning: Overseas engineer dispatch available.

On-Site Training: Ensure safe and efficient operation.

24/7 Online Support: Rapid response for any technical needs.

Warranty & Lifelong Care: One-year free maintenance and lifetime service support.

Parameter

| Model | Steam Capacity(t/h) | Rated Pressure (Mpa) | Rated Steam Temeperature (℃) | Thermal Efficiency(%) | Design Fuel |

| DHL20 | 20 | 1.25/1.6/2.0/2.5/3.82 | 194/204/250/320/450 | 89—92 | coal, biomass, wood chips, biomass pellet, bagasse, rice husk, palm kernel shell etc. |

| DHL25 | 25 | 1.25/1.6/2.0/2.5/3.82 | 194/204/250/320/450 | 89—92 | |

| DHL30 | 30 | 1.25/1.6/2.0/2.5/3.82 | 194/204/250/320/450 | 89—92 | |

| DHL35 | 35 | 1.25/1.6/2.0/2.5/3.82 | 194/204/250/320/450 | 89—92 | |

| DHL40 | 40 | 1.25/1.6/2.0/2.5/3.82 | 194/204/250/320/450 | 89—92 | |

| DHL50 | 50 | 1.25/1.6/2.0/2.5/3.82 | 194/204/250/320/450 | 89—92 | |

| DHL75 | 75 | 1.25/1.6/2.0/2.5/3.82/5.3 | 194/204/250/320/450 | 89—92 | |

| Note: Parameter is for reference only, if any changes should follow the actual drawing | |||||

| Boiler Model | Rated Thermal Power(MW) | Rated Working Pressure(MPa) | Rated Outlet Water Temperature (℃) | Rated Intake Temperature (℃) | |

| DHL29-1.25/130/70-M | 29 | 1.25 | 130 | 70 | |

| DHL46-1.6/150/90-M | 46 | 1.6 | 150 | 90 | |

| DHL58-1.6/150/90-M | 58 | 1.6 | 150 | 90 | |

| DHL70-1.6/150/90-M | 70 | 1.6 | 150 | 90 |

Relate Cases

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler