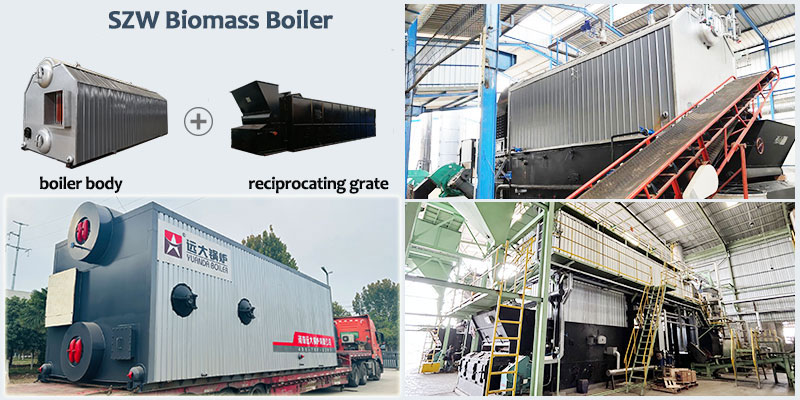

SZW biomass boiler | Step grate biomass boiler | Water tube boiler

SZW reciprocating grate boiler is also named as step grate boiler. Compared with other types of boilers, reciprocating grate biomass boilers are more suitable for burning biomass fuels with high moisture and low calorific value. Of course, this kind of boiler has a larger steam separation area, provides high-quality steam, larger steam storage capacity, etc.

| Output: | steam/hot water |

| Capacity: | 4 ton/h-50 ton/h |

| Horsepower | 250hp to 2500hp |

| Available Fuel: | briquettes, wood waste, empty fiber bunches,rice husk, bagasse, palm kennel, forest waste |

| Applied Industries: | sugar, chemical, paper, textile, food, pharmaceuticals, heating industry and construction industry, etc |

All-round Biomass Boiler Solution

SZW/DZW type reciprocating grate boiler, also known as a stepped grate boiler, pusher grate boiler, is a "all-round biomass boiler", mainly composed of boiler body and combustion equipment. It can convert solid fuel such as biomass, wood chips, wood waste into steam/hot water or electricity.

Unlike other types of boilers, reciprocating grate biomass boiler are specifically designed for various biomass fuels, especially with high moisture content and low calorific value. Such wood chips, sawdust, rice husk, wood waste, palm fiber, forestry waste, nut shell, coconut shell, straw, biomass pellets, and bagasse...

It can minimize fuel costs and achieve high economic benefits; stable and efficient operation with water-tube structure; modular design makes installation and maintenance simple.

One-stop boiler solution: Supply complete system including automatic feeding system, boiler body, combustion equipment, flue gas purification system, soft water treatment system, waste heat recovery system and PLC automatic control system.

High Fuel adaptability: Reduces fuel costs, and unaffected by fluctuations in a single fuel market.

High efficiency and reliability: Ensures continuous production and provides stable high-temperature, high-pressure steam.

Economical operation: Significantly saves investment and yields substantial long-term economic benefits.

Automation and intelligence: Reduces labor costs and operational complexity, and improves management efficiency.

Environmental compliance: Meets emission requirements and enhances the company's green image.

1. High fuel adaptability

√ Wide Applicability - Specifically designed for various biomass fuels, it can efficiently burn various high-moisture, high-ash, low calorific value biomass fuels, such wood waste, woodchips, sawdust, palm shells, rice husks, bagasse, forest waste, etc.

√ Low Fuel Cost - Can use wood waste, agricultural/forestry waste. It is especially suitable for timber processing plants, palm oil mills, rice mills, oil pressing plants, pallet factories, and agricultural product processing plants, converting waste into fuel and significantly reducing operating costs.√ No Size Limited - Supports various fuel forms such as flakes, blocks, chips, granules, powders, etc.

2. Advanced Combustion Technology

√ Three Step Burning Process - The grate has three burning zones "preheating + main combustion + burnout." Fuel goes through four steps – drying, pyrolysis, combustion, and burnout—on the moving grate, ensuring complete combustion and a combustion efficiency of ≥90%.

√ Smart Air Control - Multiple independent air chambers under the grate allow for precise airflow adjustment based on the combustion stage, effectively controlling the excess air coefficient and maximizing combustion efficiency.

√ Active Slag Breaking and Self-Cleaning - The reciprocating motion of the grate effectively breaks up surface slag and automatically removes ash, maintaining smooth grate ventilation and preventing a decrease in thermal efficiency due to slag buildup.

3. Stable and Reliable Operation with a High Degree of Automation

Water-tube Boiler Proper - The water-tube structure facilitates water circulation, resulting in high-quality steam, high safety, and the ability to withstand higher pressures. Also can produce high-temperature superheated steam(such as power generation and special drying).

Robust Grate Design - The grate bars are made of heat-resistant cast steel, ensuring a long service life and easy maintenance and replacement.

Wide Load Adjustment - The boiler can operate stably within a load range of 30%-110%, with rapid response, effectively adapting to fluctuations in production line demands.

Continuous and stable operation - The unique grate structure ensures uniform fuel delivery, supporting 24/7 uninterrupted operation.

Fully Automatic Control - Equipped with an advanced PLC or DCS control system, it achieves automatic feeding, automatic ignition, automatic air-fuel ratio adjustment, automatic ash removal, fault alarms and protection, greatly reducing reliance on operators.

Fault Monitoring - Real-time monitoring of operating parameters; automatic alarm and activation of protection programs in case of abnormalities.

4. Easy and Quick Installation, Saving Time and Effort

Modular Design - Boiler body, feeding system, and dust removal system are pre-assembled at the factory, reducing on-site work and shortening the installation cycle.

Simple Foundation Requirements - No special foundation is required; conventional concrete foundations are sufficient for installation.

Standardized Connection - Standard interfaces are provided for quick connection.

5. Easy Maintenance and Long Service Life

Few Easy-to-Break Parts - The grate is made of special heat-proof steel and can last 5 years or more.

Convenient Maintenance - Multiple inspection doors and observation holes allow for maintenance without shutting down the boiler.

Automated Ash Removal - Equipped with an automatic ash removal equipment, soot blower, effectively removing ash from the heated surface and maintaining long-term high-efficiency operation.

6. Extremely Low Emissions, Significant Social Benefits

Ultra-Low Emissions - Using clean burning inside boiler plus smoke cleaning system (cyclone, bag filter, wet washer). This makes: Dust in smoke ≤ 20mg/m³ NOx gas ≤ 150mg/m³. Meets environmental rules in most countries.

Turn Waste into Value - Changes biomass or forest waste into useful energy. Solves waste disposal problem and brings extra income. Supports green recycling economy.

Company Strength

■ Founded in 1956, a premium supplier assessed, certified, and inspected by SGS Group. Leading industrial boiler manufacturer in China.

■ Holds international boiler certifications: CE, ASME, DOSH, EAC, GOST, ISO

■ Over 17 years of export experience, gold-level supplier, ensuring payment and delivery.

■ Professional team integrating R&D, production, sales, and service.

■ 53,053㎡ Factory area, supporting video/VR factory audits or third-party inspections.

■ Engineers serving over 50 countries.

■ Products sold to over 130 countries/regions, covering food, beverage, textiles, paper, wood industries. Serving over 100,000 customers.

Products & Technology

■ Diverse Product Range: Fire-tube boilers, water-tube boilers, water-fire-tube boilers, combined boilers, vertical boilers, cogeneration boilers, waste heat recovery boilers, skid-mounted boilers, and mobile containerized boilers.

■ Flexible Fuels: Supports various fuels such as natural gas, biogas, lpg, diesel, heavy oil, dual fuels, coal, biomass, wood chips, sawdust, bagasse, wood residue, sawdust, forest waste, palm shells, hybrid biomass/gas, palm fiber, rice husks, walnut shells, electricity, etc.

■ Collaboration with advanced boiler research institutes ensures advanced technology and high energy efficiency.

Services & Markets

■ Local Projects: We have installed many boiler projects in different countries, can provide boiler case studies.

■ High Repurchase Rate: 55% of our customers are repeat customers or referral customers.

■ Local Support: We have long-term, reliable local agents, can provide one-stop service from installation and training to maintenance.

■ Comprehensive Service: From project planning to after-sales support, we provide comprehensive support throughout the whole boiler life, with 24/7 online support and immediate response.

Why believe Yuanda boiler quality?

(1) Strength calculation report with applied materials information;

(2) 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3) 100% X-ray inspection( (Longitudinal, transversal safety inspection)): ensure the quality of entire boiler;

(4) Hydrostatic test: ensure the standard working pressure and safety;

(5) Third-party inspection report

(6) Passed ASME CE ISO DOSH EAC GOST boiler level certificate.

Service

Comprehensive Boiler Solutions – From Planning to Lifetime Support

Pre-Sales Support:Expert Design Guidance: Help you select the optimal boiler model tailored to your industry needs.

Detailed Technical Documentation: Provide certificates, CAD drawings, consumption analysis, and boiler room planning.

Customized Solutions: Deliver complete system designs including installation material lists.

Competitive Pricing: Factory-direct rates with uncompromised quality.

After-Sales Assurance:Genuine Spare Parts: Original components with reliable supply.

Global Installation & Commissioning: Overseas engineer dispatch available.

On-Site Training: Ensure safe and efficient operation.

24/7 Online Support: Rapid response for any technical needs.

Warranty & Lifelong Care: One-year free maintenance and lifetime service support.

Parameter

| Boiler model | Rated capacity | Rated | Rated steam temp. | Feed water temp. | Exhaust gas temp. | Design effiency | Boiler water volume | Weight | Dimension | Delivery mode |

| pressure | ||||||||||

| ton/h | Mpa | ºC | m2 | ºC | % | m3 | ton | mm | ||

| SZL2 | 2 |

1.25/1.6/1.8/ 2.5/3.82 |

194/204/ 226/300/350/450 |

20/105 | 130.67 | 83.13 | 6.76 | 22 | 5900×2850×3460 | Package |

| SZL4 | 4 | 142 | 84.23 | 5.1 | 29 | 6460×3280×3462 | Package | |||

| SZL6 | 6 | 142 | 84.81 | 8.4 | 34 | 7830×3560×3462 | Package | |||

| SZL8 | 8 | 149.15 | 85.02 | 9.4 | 40.5 | 8870×3670×3462 | Package | |||

| SZL10 | 10 | 152.7 | 86.2 | 8.35 | 24 | 7645×3180×3526 | Assembly | |||

| SZL12 | 12 | 148.7 | 86.56 | 12.8 | 37 | 9258×3294×3524 | Assembly | |||

| SZL15 | 15 | 149.86 | 86.29 | 15.5 | 24.7 | 11010×3300×2200 | Assembly | |||

| SZL20 | 20 | 147.4 | 86.8 | 15.8 | 25.97 | 16680×6200×8420 | Assembly | |||

| SZL25 | 25 | 149.6 | 86.4 | 16.5 | 28 | 8300×3000×3600 | Semi-Assembly | |||

| SZL30 | 30 | 148.6 | 86.8 | 16.8 | 29 | 8500×3600×3640 | Semi-Assembly | |||

|

Notice: For place limited, we didnot list all models. Please contact us directly for get specifics. |

||||||||||

Relate Cases

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler