rice mill boiler | paddy rice steam boiler | biomass fired boiler

Rice husk fired boiler is Yuanda special design industrial boiler upon husk fuel, has patent technical, fully automatic boiler. It has the advantages of high thermal efficiency, avoid coking, low cost, environment protect, widely used for rice mill plant.

| Output: | steam |

| Thermal Capacity: | 0.5-40 ton/h |

| Styles: | horizontal |

| Available Fuel: | rice husk, all kinds of biomass fuel<5cm |

| Applied Industries: | rice mill, food, beverage, diaries, feed mill, garment, textile mill, paper mill, packaged, refinery, chemical etc |

Introduction

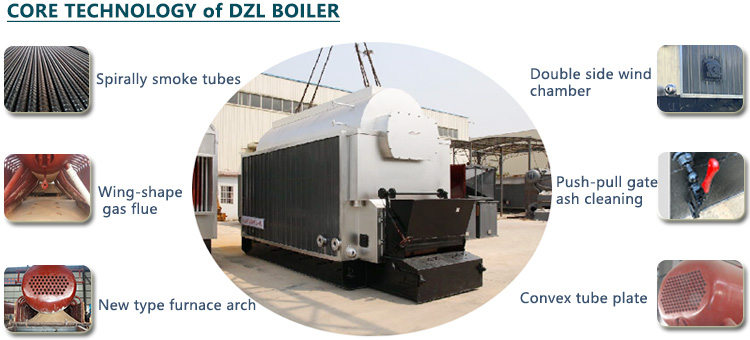

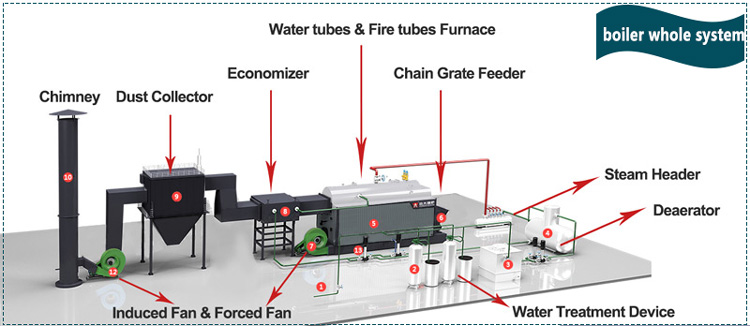

Yuanda DZL-VII type rice husk fired boiler adopts horizontal three-pass flue gas flow structure, automatic chain grate, unique furnace design, and thread smoke tube technologies, water-fire tube mixed boiler with 5-th water level protection, high-matching PLC smart control. This boiler is called as “Revolution of Industrial Boilers” both by domestic and abroad market.

DZL husk fired boiler usually used for rice production line, steam capacity is in 0.5ton/h to 40ton/h. Also can be customized for special fuels such as Coal, Coconut Shell, Wood, Sawdust, Palm waste, Waste Fabrics etc.

| Boiler model | DZL1 | DZL2 | DZL4 | DZL6 | DZL8 | DZL10 | DZL12 | DZL15 | DZL20 |

| Rated steam capacity(ton/hr) | 1 ton | 2 ton | 4 ton |

6 ton |

8 ton | 10 ton | 12 ton | 15 ton | 20 ton |

| Rated steam pressure(mpa) |

0.4/0.7/1.0/1.25/1.6/2.0/2.5/3.82 |

||||||||

WNS-T is a rice husk fired boiler that is a combination of a biomass burner and fire tube boiler, and is more popular because of its flexibility. It can convert to gas fired or oil fired It can convert to gas fired or oil fired if required. The thermal effiency is a little lower than DZL type.

Why Choose Us:

■ Established in 1956, as a stated owned enterprise.

■ Over 16 years export experiences, payment & shipping protection

■ CE ASME DOSH EAC GOST ISO high standard boiler certified

■ Production of various types boilers, provide pre-sale boiler proposal for customer select

■ Directly factory low price & quality protection.

■ Completed technology & after-sale service team.

■ Support Video/VR inspection. Abroad installation and commissing service etc

■ Technical discussion, drawing about boiler solution for your company use

Boilers We Have:

① Steam Boiler/Generator (the boiler can produce pressure steam/vapor for production process) , Hot Water Heater Boiler (ther boiler can provide hot water or central heating for use), Thermal Oil Heater Boiler (heating oil purpose, hot oil circulation boiler), Turbine Boiler (drive turbine, to generating electricity)

② Fuel can be: Gas, Lpg, Diesel, Heavy Oil, Coal, Wood, Biomass, Charcoal, Briquette, Pellets, Waste Fabric, Husk, Fruit Shells, Forest Waste, Paper Waste etc

③ Sructure has: Fire Tube Boiler, Water Tube Boiler, Water-Fire Tube Boiler, Chain Grate Boiler, Reciprocating Grate Boiler, Step Grate Boiler, Traveling Grate Boiler

---- Welcome to inquiry, If you need boiler ----

Parameter

| Model |

Rated steam output (Ton/hr) |

Rated steam pressure (Mpa) |

Rated steam temperature (℃) |

Feed water temperature (℃) |

Thermal efficiency(%) | Fuel consumption(Kg/h) |

| DZL 1-0.7/1.0/1.25/1.6-T | 1 | 0.4 to 2.5 (4-25 in bar) | 130~226 | 20/105 | >84 | 140 |

| DZL 2-0.7/1.0/1.25/1.6-T | 2 | 0.4 to 2.5 (4-25 in bar) | 130~226 | 20/105 | >84 | 280 |

| DZL 4-0.7/1.0/1.25/1.6-T | 4 | 0.4 to 2.5 (4-25 in bar) | 130~226 | 20/105 | >84 | 570 |

| DZL 6-0.7/1.0/1.25/1.6-T | 6 | 0.4 to 2.5 (4-25 in bar) | 130~226 | 20/105 | >84 | 810 |

| DZL 8-0.7/1.0/1.25/1.6-T | 8 | 0.4 to 2.5 (4-25 in bar) | 130~226 | 20/105 | >84 | 1100 |

| DZL 10-0.7/1.0/1.25/1.6-T | 10 | 0.4 to 2.5 (4-25 in bar) | 130~226 | 20/105 | >84 | 1380 |

| DZL 15-0.7/1.0/1.25/1.6-T | 15 | 0.4 to 2.5 (4-25 in bar) | 130~226 | 20/105 | >84 | 2100 |

| DZL 20-0.7/1.0/1.25/1.6-T | 20 | 0.4 to 2.5 (4-25 in bar) | 130~226 | 20/105 | >84 | 2600 |

| Note: Standard boiler parameter is for your reference, should follow the actual technical data according customer needs & engineer design. | ||||||

Relate Cases

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler