Wood Gasification Boiler | Biomass Gasification Burner | Biomass Gas Boiler

Yuanda Boiler high-efficiency biomass gasification boilers. Convert woodchips, wood waste, forest waste into clean energy for industrial steam & hot water. Lower fuel costs, reduce emissions.

| Output: | steam/hot water |

| Capacity: | 1 ton/h-50 ton/h |

| Horsepower | 250hp to 2500hp |

| Available Fuel: | biomass, woodchips, sawdust, wood sanding powder, rice husk, palm shell, wood residue, forest waste, agro waste etc... |

| Applied Industries: | sugar, chemical, paper, textile, food, pharmaceuticals, heating industry and construction industry, etc |

Introduction

Yuanda Boiler biomass gasification boiler is an advanced thermal system that doesn't just burn biomass—it converts it into valuable energy with exceptional efficiency. Through a controlled thermochemical process, solid fuels like wood chips, sawdust, rice husk, palm shell waste and agricultural waste are transformed into a clean-burning combustible gas. This gas is fully combusted in boiler to generate steam or hot water for a wide range of industrial applications.

This technology represents a significant leap from traditional biomass boilers, offering superior fuel flexibility, unparalleled thermal efficiency, and a dramatic reduction in emissions. It is the ideal solution for businesses seeking to lower operational costs, achieve sustainability goals, and secure energy independence.

Biomass gasification boilers can process a variety of biomass feedstocks and convert them into green energy. We can also provide customized designs based on the type of fuel our clients process to achieve the highest energy conversion efficiency. Common biomass feedstocks include wood chips, sawdust, rice husks, wood waste, palm waste, forestry waste, nut shells, coconut shells, straw, biomass pellets, bagasse, etc.

Key Features & Advanced Design

Two-Stage Gasification Technology

The core of our system. Biomass is first converted into gas in a dedicated gasification chamber. The resulting syngas then moves to a separate combustion chamber for clean, complete burning, maximizing heat transfer and minimizing pollutants.

Wide Fuel Adaptability

Efficiently processes various biomass fuels, including wood blocks, pellets, rice husks, straw, and other agro-waste, giving you flexibility in fuel sourcing.

High Thermal Efficiency

With optimized furnace design and enhanced heat exchange surfaces, our boilers achieve thermal efficiencies of over 88%, ensuring you get the most energy from every kilogram of fuel.

Automated & Intelligent Control

A user-friendly PLC control system allows for automatic operation, including feed control, ignition, and temperature regulation. Real-time monitoring and self-diagnostics ensure safe and hassle-free operation.

Robust Construction

Built with high-quality pressure vessel steel and refractory materials to ensure a long service life, even under demanding conditions.

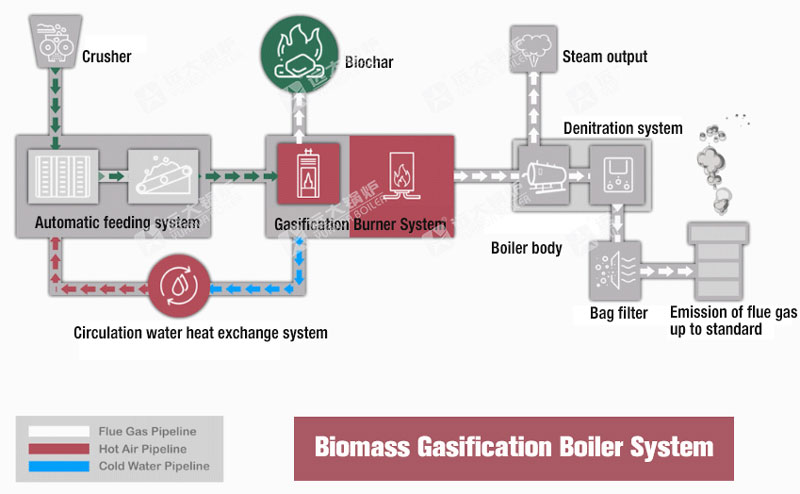

Main System

Biomass gasification boiler system can convert organic waste such as biomass, agricultural, and forestry waste into electricity and steam/hot water. It mainly includes the following six systems:

1. Raw Material System: This system includes equipment such as crushers and automatic feeders. Its main function is to pre-treat the biomass raw materials, crushing them into sizes suitable for subsequent gasification processes. This system ensures uniform distribution of the raw materials during gasification, thereby maximizing gasification efficiency.

2. Gasification Combustion Unit: One of the core pieces of equipment in a biomass gasification boiler, its main function is to pyrolyze biomass and produce products such as syngas, biochar, and tar.

3. Boiler Body: Another core piece of equipment in a biomass gasification boiler system. It is a double-drum water-tube boiler with a fully membrane-type water-cooled wall structure, a large furnace area, and complete combustion.

4. Flue Gas Purification System: This system mainly includes bag filters, ceramic multi-tube dust collectors, fans, and chimneys for emission control.

5. Soft Water Treatment System & Circulating Water Heat Exchange System: Soft water treatment, water tank, utilizing waste heat to heat feedwater and improve boiler thermal efficiency, etc.

6. Automated Control System: PLC intelligent control system, enabling real-time monitoring of the entire system to ensure safe and stable operation.

Benefit

Drastic Reduction in Fuel Costs: Biomass fuel is often significantly cheaper than fossil fuels like natural gas, diesel, or coal, leading to a rapid return on investment.

Eco-Friendly & Compliant Operation: The complete gasification and combustion process results in extremely low emissions of particulate matter and unburned hydrocarbons, helping you meet stringent environmental regulations.

Turnkey Waste-to-Energy Solution: Ideal for industries with their own biomass waste streams (e.g., wood processing plan, palm oil mill, rice mill, plywood factory, agriculture). Convert your waste disposal problem into a valuable energy source.

Enhanced Energy Security: Reduce your reliance on volatile fossil fuel markets and price fluctuations by switching to locally available, renewable biomass.

Our biomass gasification boilers are perfectly suited for industries requiring process hot water or steam.

Applications

Food & Beverage Processing: For sterilization, cooking, drying, and washing.

Textile & Dyeing Plants: Providing steam for dyeing, drying, and finishing processes.

Wood & Timber Processing: Lumber drying, panel pressing (MDF, particleboard), and utilizing wood waste.

Agricultural Sector: Greenhouse heating, crop drying, and processing agricultural residues.

Chemical & Industrial Plants: For process heating and steam generation.

District Heating Systems: Supplying heat to residential, commercial, or institutional buildings.

We offer customized boiler systems tailored to your specific fuel and operational needs, backed by comprehensive technical support.

Company Strength

■ Founded in 1956, a premium supplier assessed, certified, and inspected by SGS Group. Leading industrial boiler manufacturer in China.

■ Holds international boiler certifications: CE, ASME, DOSH, EAC, GOST, ISO

■ Over 17 years of export experience, gold-level supplier, ensuring payment and delivery.

■ Professional team integrating R&D, production, sales, and service.

■ 53,053㎡ Factory area, supporting video/VR factory audits or third-party inspections.

■ Engineers serving over 50 countries.

■ Products sold to over 130 countries/regions, covering food, beverage, textiles, paper, wood industries. Serving over 100,000 customers.

Products & Technology

■ Diverse Product Range: Fire-tube boilers, water-tube boilers, water-fire-tube boilers, combined boilers, vertical boilers, cogeneration boilers, waste heat recovery boilers, skid-mounted boilers, and mobile containerized boilers.

■ Flexible Fuels: Supports various fuels such as natural gas, biogas, lpg, diesel, heavy oil, dual fuels, coal, biomass, wood chips, sawdust, bagasse, wood residue, sawdust, forest waste, palm shells, hybrid biomass/gas, palm fiber, rice husks, walnut shells, electricity, etc.

■ Collaboration with advanced boiler research institutes ensures advanced technology and high energy efficiency.

Services & Markets

■ Local Projects: We have installed many boiler projects in different countries, can provide boiler case studies.

■ High Repurchase Rate: 55% of our customers are repeat customers or referral customers.

■ Local Support: We have long-term, reliable local agents, can provide one-stop service from installation and training to maintenance.

■ Comprehensive Service: From project planning to after-sales support, we provide comprehensive support throughout the whole boiler life, with 24/7 online support and immediate response.

Quality Assurance

(1) Strength calculation report with applied materials information;

(2) 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3) 100% X-ray inspection( (Longitudinal, transversal safety inspection)): ensure the quality of entire boiler;

(4) Hydrostatic test: ensure the standard working pressure and safety;

(5) Third-party inspection report

(6) Passed ASME CE ISO DOSH EAC GOST boiler level certificate.

Service

Comprehensive Boiler Solutions – From Planning to Lifetime Support

Pre-Sales Support:Expert Design Guidance: Help you select the optimal boiler model tailored to your industry needs.

Detailed Technical Documentation: Provide certificates, CAD drawings, consumption analysis, and boiler room planning.

Customized Solutions: Deliver complete system designs including installation material lists.

Competitive Pricing: Factory-direct rates with uncompromised quality.

After-Sales Assurance:Genuine Spare Parts: Original components with reliable supply.

Global Installation & Commissioning: Overseas engineer dispatch available.

On-Site Training: Ensure safe and efficient operation.

24/7 Online Support: Rapid response for any technical needs.

Warranty & Lifelong Care: One-year free maintenance and lifetime service support.

Parameter

| Boiler model | Rated capacity | Rated | Rated steam temp. | Feed water temp. | Exhaust gas temp. | Design effiency | Boiler water volume | Weight | Dimension | Delivery mode |

| pressure | ||||||||||

| ton/h | Mpa | ºC | m2 | ºC | % | m3 | ton | mm | ||

| SZL2 | 2 |

1.25/1.6/1.8/ 2.5/3.82 |

194/204/ 226/300/350/450 |

20/105 | 130.67 | 83.13 | 6.76 | 22 | 5900×2850×3460 | Package |

| SZL4 | 4 | 142 | 84.23 | 5.1 | 29 | 6460×3280×3462 | Package | |||

| SZL6 | 6 | 142 | 84.81 | 8.4 | 34 | 7830×3560×3462 | Package | |||

| SZL8 | 8 | 149.15 | 85.02 | 9.4 | 40.5 | 8870×3670×3462 | Package | |||

| SZL10 | 10 | 152.7 | 86.2 | 8.35 | 24 | 7645×3180×3526 | Assembly | |||

| SZL12 | 12 | 148.7 | 86.56 | 12.8 | 37 | 9258×3294×3524 | Assembly | |||

| SZL15 | 15 | 149.86 | 86.29 | 15.5 | 24.7 | 11010×3300×2200 | Assembly | |||

| SZL20 | 20 | 147.4 | 86.8 | 15.8 | 25.97 | 16680×6200×8420 | Assembly | |||

| SZL25 | 25 | 149.6 | 86.4 | 16.5 | 28 | 8300×3000×3600 | Semi-Assembly | |||

| SZL30 | 30 | 148.6 | 86.8 | 16.8 | 29 | 8500×3600×3640 | Semi-Assembly | |||

|

Notice: For place limited, we didnot list all models. Please contact us directly for get specifics. |

||||||||||

Relate Cases

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler