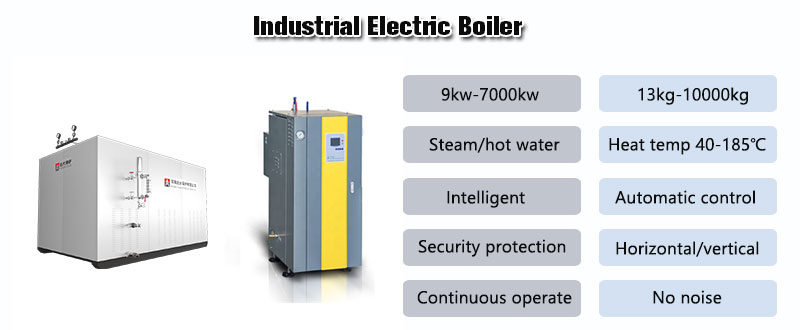

Electric steam boiler | Electric hot water boiler | Eco-friendly boiler

YUANDA electric boiler is meet low/high pressure steam and hot water requirements for industrial, commercial, and specialized uses. They are clean, quiet, easy to install and compact. No fuel combustion considerations, no chimney and emissions worry.

| Transfer Medium: | steam, hot water |

| Capacity: | 9-7000kw, 0.05-10 ton |

| Horsepower: | 6-700hp |

| Style: | horizontal, vertical |

| Applied Industry: | laundry, resort, hotel, building, hospital, food, beverage, autoclave, dairy, feed mill, garment, textile, pharm, concrete etc |

Introduction

YUANDA electric boiler is designed for industrial processes requiring high temperatures steam and hot water. High thermal efficiency, no noise, no pollution, automatic control.

Two types horizontal electric boiler and vertical electric boiler for choose, with transfarmer and electrical control panel.

Widely use for food and beverage machinery, washing and ironing equipment, building materials and plastics machinery, papermaking and printing equipment, chemical extraction equipment, pharmaceutical equipment, etc.

LDR vertical electric boiler, also known as steam generator, electric steam generator, small electric boiler, stainless steel boiler. Cabinet design style, Composed of electric heating elements, components, drums, accessories, strong and weak current controlsystems, etc.

Main characteristics:

● Power 9kw-350kw, steam capacity 13kg-500kg

● Produce steam/hot water within 3-5 minutes

● Pressure up to 10 kg/cm²

● One key to start

● Small food print

● All internal piping and boiler control system has been connected before delivering the factory

Main characteristics:

● Power 210kw-7000kw, steam capacity 300kg-10.000kg

● Produce steam within 20 minutes

● Pressure up to 20 kg/cm²

● Separate boiler body and control cabinet

● Automatic blow-down system

● Large load adjustment range

1. Electric operation does not require gas/oil supply and chimney system

2. Pipes and wires pre-installed in the factory

3. Control panel with system visualization

4. Individual designed as per customer needs

5. Good accessibility for maintenance and checks due to the removable inspection box and removable panels

6. Internal steam-water seperator, high amount of steam

7. No pollution, no noise

8. No combustion chamber, no chimney, no heat loss, thermal efficiency is above 98%

9. Multiple protection voltage, water level, power supply and pressure

10. The boiler heating group can be set as required

Company Strength

■ Founded in 1956, a premium supplier assessed, certified, and inspected by SGS Group. Leading industrial boiler manufacturer in China.

■ Holds international boiler certifications: CE, ASME, DOSH, EAC, GOST, ISO

■ Over 17 years of export experience, gold-level supplier, ensuring payment and delivery.

■ Professional team integrating R&D, production, sales, and service.

■ 53,053㎡ Factory area, supporting video/VR factory audits or third-party inspections.

■ Engineers serving over 50 countries.

■ Products sold to over 130 countries/regions, covering food, beverage, textiles, paper, wood industries. Serving over 100,000 customers.

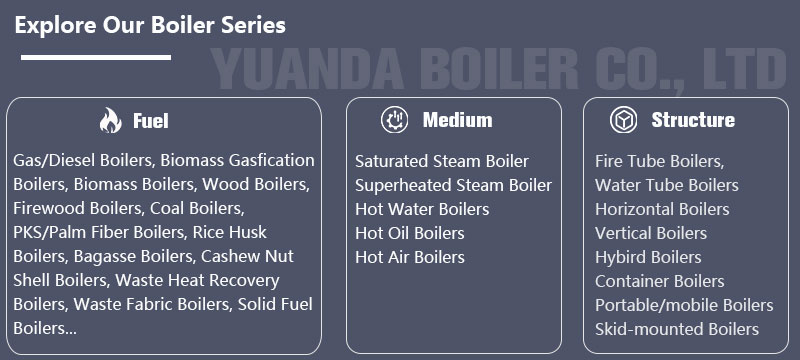

Products & Technology

■ Diverse Product Range: Fire-tube boilers, water-tube boilers, water-fire-tube boilers, combined boilers, vertical boilers, cogeneration boilers, waste heat recovery boilers, skid-mounted boilers, and mobile containerized boilers.

■ Flexible Fuels: Supports various fuels such as natural gas, biogas, lpg, diesel, heavy oil, dual fuels, coal, biomass, wood chips, sawdust, bagasse, wood residue, sawdust, forest waste, palm shells, hybrid biomass/gas, palm fiber, rice husks, walnut shells, electricity, etc.

■ Collaboration with advanced boiler research institutes ensures advanced technology and high energy efficiency.

Services & Markets

■ Local Projects: We have installed many boiler projects in different countries, can provide boiler case studies.

■ High Repurchase Rate: 55% of our customers are repeat customers or referral customers.

■ Local Support: We have long-term, reliable local agents, can provide one-stop service from installation and training to maintenance.

■ Comprehensive Service: From project planning to after-sales support, we provide comprehensive support throughout the whole boiler life, with 24/7 online support and immediate response.

Quality Control

(1) Strength calculation report with applied materials information;

(2) 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3) 100% X-ray inspection( (Longitudinal, transversal safety inspection)): ensure the quality of entire boiler;

(4) Hydrostatic test: ensure the standard working pressure and safety;

(5) Third-party inspection report

(6) Passed ASME CE ISO DOSH EAC GOST boiler level certificate.

Service

Comprehensive Boiler Solutions – From Planning to Lifetime Support

Pre-Sales Support:Expert Design Guidance: Help you select the optimal boiler model tailored to your industry needs.

Detailed Technical Documentation: Provide certificates, CAD drawings, consumption analysis, and boiler room planning.

Customized Solutions: Deliver complete system designs including installation material lists.

Competitive Pricing: Factory-direct rates with uncompromised quality.

After-Sales Assurance:Genuine Spare Parts: Original components with reliable supply.

Global Installation & Commissioning: Overseas engineer dispatch available.

On-Site Training: Ensure safe and efficient operation.

24/7 Online Support: Rapid response for any technical needs.

Warranty & Lifelong Care: One-year free maintenance and lifetime service support.

Parameter

| Model | Rated capacity | Input power | Rated pressure | Steam temperature | Thermal efficiency | Dimension | Weight |

| Unit | kg/h | kw | Mpa | ºC | % | mm | kg |

| LDR0.013-0.7 | 13 | 9 | 0.7 | 171 | 99.9 | 650×390×750 | 70 |

| LDR0.017-0.7 | 17 | 12 | 0.7 | 171 | 99.9 | 650×390×750 | 75 |

| LDR0.025-0.7 | 25 | 18 | 0.7 | 171 | 99.9 | 750×450×1050 | 90 |

| LDR0.035-0.7 | 35 | 24 | 0.7 | 171 | 99.9 | 750×520×1050 | 95 |

| LDR0.05-0.7 | 50 | 36 | 0.7 | 171 | 99.9 | 750×580×1150 | 101 |

| LDR0.065-0.7 | 65 | 48 | 0.7 | 171 | 99.9 | 800×580× 1200 | 115 |

| LDR0.075-0.7 | 75 | 54 | 0.7 | 171 | 99.9 | 800×580× 1300 | 140 |

| LDR0.085-0.7 | 85 | 60 | 0.7 | 171 | 99.9 | 800×600× 1300 | 145 |

| LDR0.1-0.7 | 100 | 72 | 0.7 | 171 | 99.9 | 860×650× 1390 | 172 |

| LDR0.11-0.7 | 110 | 80 | 0.7 | 171 | 99.9 | 860×650× 1390 | 185 |

| LDR0.125-0.7 | 125 | 90 | 0.7 | 171 | 99.9 | 860×650× 1430 | 190 |

| LDR0.15-0.8 | 150 | 108 | 0.8 | 175 | 99.9 | 920×760×1600 | 245 |

| LDR0.18-0.8 | 180 | 126 | 0.8 | 175 | 99.9 | 920×760× 1600 | 260 |

| LDR0.2-0.8 | 200 | 144 | 0.8 | 175 | 99.9 | 1130×750× 1780 | 450 |

| LDR0.25-0.8 | 250 | 180 | 0.8 | 175 | 99.9 | 950×900× 1830 | 650 |

| LDR0.3-0.8 | 300 | 216 | 0.8 | 175 | 99.9 | 1320×1040× 1920 | 760 |

| LDR0.4-0.8 | 400 | 288 | 0.8 | 175 | 99.9 | 1380×1040× 2070 | 890 |

| LDR0.5-0.8 | 500 | 360 | 0.8 | 175 | 99.9 | 1020×890× 2350 | 1020 |

| WDR0.5-1.0 | 500 | 360 | 1 | 184 | 98 | 1755*1180*1510 | 1400 |

| WDR1.0-1.0 | 1000 | 700 | 1 | 184 | 98 | 2530*1380*1480 | 1730 |

| WDR2-1.0 | 2000 | 1400 | 1 | 184 | 98 | 2530*2000*2080 | 2730 |

| WDR3-1.25 | 3000 | 2100 | 1.25 | 194 | 98 | 2630*2210*2160 | 3420 |

| WDR4-1.25 | 4000 | 2800 | 1.25 | 194 | 98 | 3680*2360*2380 | 4320 |

| WDR5-1.25 | 5000 | 3500 | 1.25 | 194 | 98 | 3980*2580*2560 | 5130 |

Relate Cases

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler