Gas Diesel Boiler | Biomass Wood Boiler | Electric Boiler

Steam boilers (steam generators) are widely used in hotel laundry room, hospital laundry center, and industrial laundry. It can iron, dry, and disinfect clothes for washing machines, dryers, ironing machines, and folders.

| Output: | saturated steam |

| Capacity: | 0.05 to 40 Ton/h, 10 to 28,000 Kw |

| Horsepower | 10hp to 2500hp |

| Pressure | 0-3.8Mpa, 0-38bar |

| Fuel type: | gas, diesel, lpg, hfo, biomass, wood, electric etc |

Introduction

Laundry boilers are industrial boilers that can be used in laundry industries, hospital laundries, and hotel laundries. Their purpose is to provide steam or hot water for washing machines, dryers, ironing machines, or folding machines for ironing, drying, and sterilizing.

Founded in 1956, Yuanda Boiler is a Class A industrial boiler and pressure vessel manufacturer with 69 years of experience. We offer premium laundry steam boiler, laundry hot water boiler, capacity from 0.1ton to 40ton, 100kw to 14000kw, with ASME CE ISO EAC DOSH certification.

WNS/LHS oil gas steam boiler Is fire tube three pass wet back with big corrugated furnace.The boiler is shipped in complete sets to ensure that the boiler can be quickly installed on site. Except for water supply, oil/gas supply and electrical connection accessories, no other building structures and special installation procedures are required. A series of inspections and commissioning work are carried out before the boiler leaves the factory to ensure the quality of the boiler. This type of boiler is mainly composed of Yuanda design boiler body, Europe original burner,Yuanda design control system, China top brand instrumentation,China top brand water pumps, USA fleck brand water treatment equipment, Yuanda design high efficiency economizer, steam header, chimney and ducts, etc.It has clean combustion, pollution-free emissions, convenient operation and sufficient output.

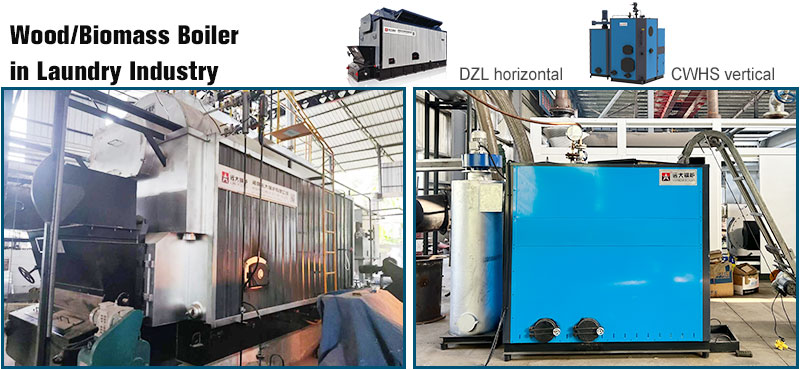

Wood biomass boiler is a fire-water tube boiler, mainly composed of the boiler body and combustion equipment. It can convert fuels such as biomass and wood into steam/hot water for laundry.

It uses a movable grate as the combustion device, and its larger and taller boiler body design is adapted to the characteristics of biomass fuel. It is equipped with valves and instruments from internationally leading brands, as well as an advanced safety interlocking system.

Electric steam boilers provide a clean and environmentally friendly steam supply for the laundry industry, producing zero pollution and operating quietly.

They utilize high-quality heating elements and thickened stainless steel tubing, and are equipped with a PLC control panel. The complete system includes a water softener, water tank, water pump, and standard auxiliary equipment. Operation is simple, requiring no complex installation; just connect to a water and power source.

Company Strength

■ Founded in 1956, a premium supplier assessed, certified, and inspected by SGS Group. Leading industrial boiler manufacturer in China.

■ Holds international boiler certifications: CE, ASME, DOSH, EAC, GOST, ISO

■ Over 17 years of export experience, gold-level supplier, ensuring payment and delivery.

■ Professional team integrating R&D, production, sales, and service.

■ 53,053㎡ Factory area, supporting video/VR factory audits or third-party inspections.

■ Engineers serving over 50 countries.

■ Products sold to over 130 countries/regions, covering food, beverage, textiles, paper, wood industries. Serving over 100,000 customers.

Services & Markets

■ Local Projects: We have installed many boiler projects in different countries, can provide boiler case studies.

■ High Repurchase Rate: 55% of our customers are repeat customers or referral customers.

■ Local Support: We have long-term, reliable local agents, can provide one-stop service from installation and training to maintenance.

■ Comprehensive Service: From project planning to after-sales support, we provide comprehensive support throughout the whole boiler life, with 24/7 online support and immediate response.

Quality Assurance

(1) Strength calculation report with applied materials information;

(2) 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3) 100% X-ray inspection( (Longitudinal, transversal safety inspection)): ensure the quality of entire boiler;

(4) Hydrostatic test: ensure the standard working pressure and safety;

(5) Third-party inspection report

(6) Passed ASME CE ISO DOSH EAC GOST boiler level certificate.

Service

Founded in 1956, Gold supplier certified by SGS Group; Over 16 years export experiences, payment&shipping protection

65 years experience, provide pre-sale boiler proposal & cost anslysis for customer select; Technical discussion, customized boiler & drawing for your company use

Directly factory low price&quality protection; With CE ASME DOSH EAC GOST ISO high standard boiler certified; Exported to 108 countries.

According to the customer production requirements, provide professional boiler solutions, cost analysis, investment budget, boiler drawing&installation and commissioning service

Parameter

| Model |

Capacity (Ton/h) |

Horspower (hp) |

Pressure (Mpa) |

steam temperature (℃) |

Feed water temperature (℃) |

Fuel consumption | |

| Light diesel oil(kg/h) | Natural gas(Nm3/h) | ||||||

| WNS 0.5 | 0.5 | 35 | 0.4 to 3.82mpa | 130~450 | 20/105 | 32.5 | 35.7 |

| WNS 1 | 1 | 71 | 0.4 to 3.82mpa | 130~450 | 20/105 | 64.6 | 70.1 |

| WNS1.5 | 1.5 | 120 | 0.4 to 3.82mpa | 130~450 | 20/105 | 96.8 | 105.2 |

| WNS 2 | 2 | 150 | 0.4 to 3.82mpa | 130~450 | 20/105 | 129.3 | 140.3 |

| WNS 3 | 3 | 200 | 0.4 to 3.82mpa | 130~450 | 20/105 | 192.9 | 212.1 |

| WNS 4 | 4 | 300 | 0.4 to 3.82mpa | 130~450 | 20/105 | 258.2 | 283.4 |

| WNS 5 | 5 | 350 | 0.4 to 3.82mpa | 130~450 | 20/105 | 323.5 | 354.7 |

| WNS 6 | 6 | 425 | 0.4 to 3.82mpa | 130~450 | 20/105 | 388.6 | 424.2 |

| WNS 8 | 8 | 550 | 0.4 to 3.82mpa | 130~450 | 20/105 | 514.6 | 566.3 |

| WNS 10 | 10 | 700 | 0.4 to 3.82mpa | 130~450 | 20/105 | 641.7 | 707.8 |

| WNS 12 | 12 | 850 | 0.4 to 3.82mpa | 130~450 | 20/105 | 768.9 | 849.3 |

| WNS 15 | 15 | 1050 | 0.4 to 3.82mpa | 130~450 | 20/105 | 960.1 | 1061.7 |

| WNS 20 | 20 | 1400 | 0.4 to 3.82mpa | 130~450 | 20/105 | 1276.2 | 1415.8 |

| Note: Standard boiler parameter is for your reference, should follow the actual technical data according customer needs & engineer design. | |||||||

Relate Cases

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler