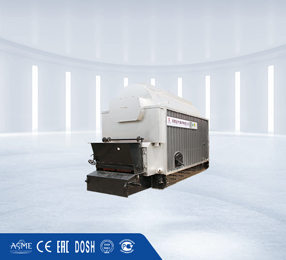

Free-installed boiler | Skid-mounted boiler | Oil gas fired boiler

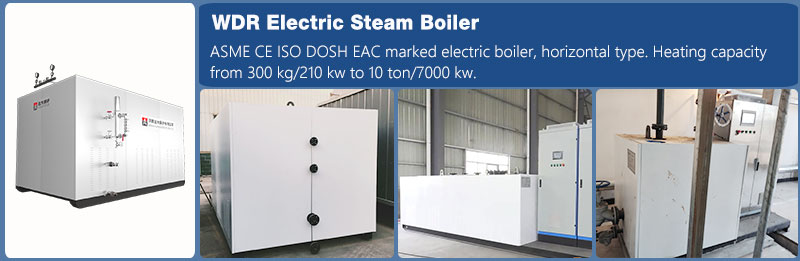

Yuanda Boiler pre-engineered, skid-mounted steam boiler and hot water boiler systems represents an all-in-one, ready-to-operate boiler solution. Capacity steam 0.3-10ton/h, hot water boiler 210kw-7000kw. User can use this boiler directly without any other installation job, present a streamlined and user-friendly approach way to company use.

| Output: | steam/hot water |

| Capacity: | 0.3ton to 10ton, 210kw to 7000kw |

| Horsepower | 10hp to 700hp |

| Pressure | 0-3.8Mpa, 0-38bar |

| Applied Industry: | food&beverage, dairy, feed, textile, paper, chemical, package, refinery, pharm, building material, hotel etc |

Introduction

Skid-Mounted Boilers, also named convenient boiler solution.

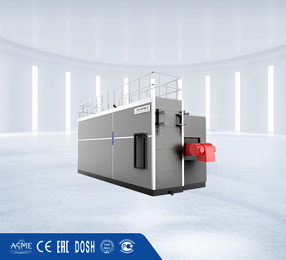

Yuanda Boiler pre-installed, skid-mounted steam boiler and hot water boiler systems represents an all-in-one, ready-to-use industrial boiler solution. The entire boiler system, including all necessary components and auxiliaries, are pre-installed and commissioned by the manufacturer is securely mounted on the skid, no need installed on-site.

Certified by ASME CE ISO DOSH EAC TUV BUV. Meet different country standard, 20+ years life assurance.

●3 pass wet-back structure, larger corugated furmace, thread smoke tube with unique expansion welding.

●Equipped with international first-level brand burner, automatic operation of ignition, flameout, big/small fire switch

●PLC automatic control, interlock system for burner, water tank, pressure, flame.

●Energy saving device, such condensate, preheater, water recovery unit etc.

01

Ready to Operate Boiler, Efficiency and Time Savings

①Reducing installation time and labor compared to conventional field-built systems; ②Easy to dismantle and reposition; ③Connect water, electricity, and gas for use within 1 day normally; ④Space-efficient with minimal footprint.

02

98.6% High Efficiency, Save Fuel and Running Cost

①Large corrugated furnace, patent design three pass smoke tubes; ②Built-in steam separator, ensure high steam quality with wetness below 1%; ③Double 12mm thickness aluminum silicate insulation layer; ④Finned tube design economizer with aluminum silicate insulation, greatly reducing heat loss.

03

High Security, 100% Safe Operation

①Anti-dry heating system with five stages water level check; ②Four stages pressure protection; ③Explosion-proof door with fire viewer; ④Remote monitoring system.

04

Long Using Life and Convenient for Maintenance

①Wet-back reverse flame chamber;②Solid round steel tension rod design;③Rapid solidification and high-strength refractory building materials;④Double opening-door at front and back.

① Water level protection, flame out protection, pressure protection, exhausted smoke over temperature protection, beside with 5th water level detector;

② Steam-water separator, high steam quality with wetness below 1%;

③ Water quality protection (dosing device, TDS system optional)

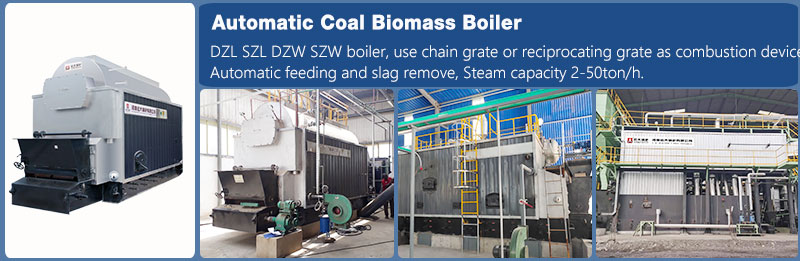

Besides our extensive range of oil and gas-fired boilers, we also proudly offer coal-fired, biomass/wood-fueled, and vertical boiler to cater to diverse customer needs.

Simply share your preferred fuel type and heating demands with us, we will be delighted to furnish you with a tailored, professional steam or hot water boiler solution.

■ Founded in 1956, a quality supplier assessed, certified and inspected by SGS Group

■ CE ASME DOSH EAC GOST TUV BUV ISO high standard boiler certification

Quality Assurance

Steel element test→Steel rust cleaning→Welding electrodes drying process→Automatic welding, argon arc welding, expansion welding etc. methods→NDT(Nondestructive Testing) including X-ray Test, Ultrasonic Test, Magnetic particle Test→Hydraulic pressure test.

FAQ of Skid-mounted Boiler

1. How much fuel does the boiler use per hour?

Take WNS 1 ton boiler as an example, the gas consumption per hour is 70m³, light diesel oil is 64kg.

2. Is there any other installation work?

No. User just need to connect the boiler with water source, electricity and fuel source, then it can work.

3. Our boiler room width is limited, how?

We have LHS vertical layout skid mounted boiler, smaller footprint than WNS boiler.

4. Do you have agent here?

We have agents and partners in some countries, will check list for you.

Parameter

| Model |

Capacity (Ton/h) |

Horspower (hp) |

Pressure (Mpa) |

steam temperature (℃) |

Feed water temperature (℃) |

Fuel consumption | |

| Light diesel oil(kg/h) | Natural gas(Nm3/h) | ||||||

| WNS 0.5 | 0.5 | 35 | 0.4 to 3.82mpa | 130~450 | 20/105 | 32.5 | 35.7 |

| WNS 1 | 1 | 71 | 0.4 to 3.82mpa | 130~450 | 20/105 | 64.6 | 70.1 |

| WNS1.5 | 1.5 | 120 | 0.4 to 3.82mpa | 130~450 | 20/105 | 96.8 | 105.2 |

| WNS 2 | 2 | 150 | 0.4 to 3.82mpa | 130~450 | 20/105 | 129.3 | 140.3 |

| WNS 3 | 3 | 200 | 0.4 to 3.82mpa | 130~450 | 20/105 | 192.9 | 212.1 |

| WNS 4 | 4 | 300 | 0.4 to 3.82mpa | 130~450 | 20/105 | 258.2 | 283.4 |

| WNS 5 | 5 | 350 | 0.4 to 3.82mpa | 130~450 | 20/105 | 323.5 | 354.7 |

| WNS 6 | 6 | 425 | 0.4 to 3.82mpa | 130~450 | 20/105 | 388.6 | 424.2 |

| WNS 8 | 8 | 550 | 0.4 to 3.82mpa | 130~450 | 20/105 | 514.6 | 566.3 |

| WNS 10 | 10 | 700 | 0.4 to 3.82mpa | 130~450 | 20/105 | 641.7 | 707.8 |

| WNS 12 | 12 | 850 | 0.4 to 3.82mpa | 130~450 | 20/105 | 768.9 | 849.3 |

| WNS 15 | 15 | 1050 | 0.4 to 3.82mpa | 130~450 | 20/105 | 960.1 | 1061.7 |

| WNS 20 | 20 | 1400 | 0.4 to 3.82mpa | 130~450 | 20/105 | 1276.2 | 1415.8 |

| Note: Standard boiler parameter is for your reference, should follow the actual technical data according customer needs & engineer design. | |||||||

| Model |

Rated heating capacity (mw) |

Rated working pressure (Mpa) |

Output water temperature (℃) |

Return water temperature (℃) |

Fuel consumption | |

| Light diesel oil(kg/h) | Natural gas(Nm3/h) | |||||

| WNS 0.35 | 0.35mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 31.6 | 36.6 |

| WNS 0.7 | 0.7mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 60.4 | 69.3 |

| WNS 1.4 | 1.4mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 122.8 | 146.1 |

| WNS 2.1 | 2.1mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 192.3 | 227.1 |

| WNS 2.8 | 2.8mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 246.1 | 286.5 |

| WNS 4.2 | 4.2mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 367.1 | 412.6 |

| WNS 5.6 | 5.6mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 490.2 | 543.7 |

| WNS 7.0 | 7.0mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 593.6 | 660.7 |

| WNS 10.5 | 10.5mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 936.5 | 998.8 |

| WNS 14 | 14mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 1200.8 | 1330.7 |

| Note: for place limited, we didn't list all models, if you need other capacity, pressure, fuel, please send us inquiry directly, we will send you detailed parameter. | ||||||

Relate Cases

Recommend Boiler

Vertical Oil / Gas Boiler

More suitable for: small space, low budget, OR steam demand of 100 to 1000 kg/h, 120 to 700 kw/h

SZS Water Tube Boiler

SZS water tube packaged gas/oil boiler, larger furnace with light membrane wall, high efficiency

Biomass Fired Boiler

Chain grate or reciprocating grate biomass boiler, burning biomass pellets, wood, shells, rice husks, bagasse, etc.

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler