SZS boiler | Gas oil fired boiler | Membrane wall boiler

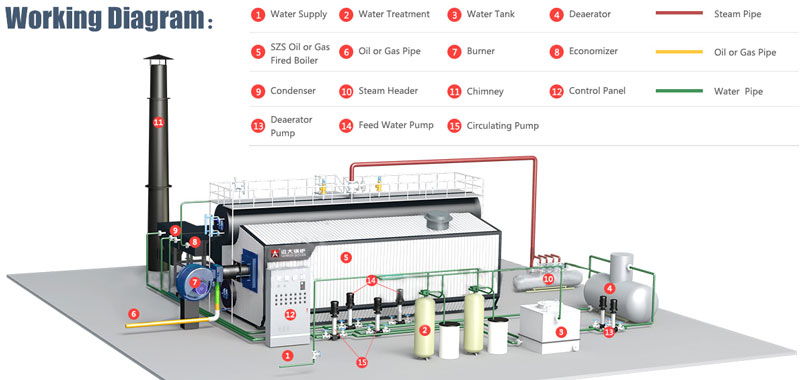

SZS oil gas fired boiler, also called water tube boiler, capacity from 4 ton to 50 ton. It adopts double drum D type vertical arrangement, full membrane wall structure, reasonale and compact layout. Quick installation, less investment in boiler house infrastructure and short installation period.

| Output: | saturated/superheated steam, hot water |

| Capacity: | 2-50ton/h, 1.4-35mw |

| Horsepower: | 150hp - 3000hp |

| Fuel: | heavy oil, diesel oil, biogas, NG, CNG, LNG, LPG, dual fuel |

| Applied Industries: | heating supply in food, beverage, textile, paper, chemical, oil field, refinery, sugar... |

SZS boiler is gas fired(oil fired) boiler with three pass return water tubes, also called fast-assembled water tube boiler. It adopts double-drum "D-type" arrangement, full water membrane wall structure, compound water circulation.

• Fuel: natural gas, lpg, cng, biogas, diesel oil, heavy oil, dual fuel

• Capacity: 4-50 ton, 300-3500hp, 2.8-35mw

• Rated Pressure:1.0mpa/1.25mpa/1.6mpa/2.5mpa/3.0mpa/3.82mpa (30psi-600psi)

• High steam temperature up to 450˚C

For saturated steam, superheated steam or hot water supply, in food, beverage, refining, petrochemical, pulp and paper, mining, manufacturing, utilities and other industries.

• Leakage protection.

1. D-type offset furnace has large furnace space, good flame filling, and sufficient combustion;

2. D-type double drum with compact structure, quick installation.

3. Pure water pipe + large upper and lower drum design, rapid pressure increase, saving operating costs;

4. Larger water volume + steam-water separation device, high steam quality;

5. Adopt full water membrane wall furnace, which has good sealing performance and good heat transfer performance.

6. Double-layer 120mm aluminum silicate insulation, the outer temperature does not exceed 45 degrees Celsius

7. The tilt angle design of the upper and lower headers makes the water flow smoother and prevents the generation of dead water areas.

8. Natural water circulation princinple, low water quality requirements and has few faults.

9. The tail is equipped with a flue gas condensation device to reduce the flue temperature and improve the thermal efficiency of the boiler;

10. Built-in soot blower for effective cleaning of superheaters and other heat transfer surfaces

11. Safe operation for over 20 years

Yuanda's philosophy: "Quality First, Integrity Wins the World, and Common Development with Customers"

Company Strength

■ Founded in 1956, a premium supplier assessed, certified, and inspected by SGS Group. Leading industrial boiler manufacturer in China.■ Products sold to over 130 countries/regions, covering food, beverage, textiles, paper, wood industries. Serving over 100,000 customers.

Products & Technology

■ Diverse Product Range: Fire-tube boilers, water-tube boilers, water-fire-tube boilers, combined boilers, vertical boilers, cogeneration boilers, waste heat recovery boilers, skid-mounted boilers, and mobile containerized boilers.■ Collaboration with advanced boiler research institutes ensures advanced technology and high energy efficiency.

Services & Markets

■ Local Support: We have long-term, reliable local agents, can provide one-stop service from installation and training to maintenance.■ High Repurchase Rate: 55% of our customers are repeat customers or referral customers.

Quality Control

(1) Strength calculation report with applied materials information;

(2) 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3) 100% X-ray inspection( (Longitudinal, transversal safety inspection)): ensure the quality of entire boiler;

(4) Hydrostatic test: ensure the standard working pressure and safety;

(5) Third-party inspection report

(6) Passed ASME CE ISO DOSH EAC GOST boiler level certificate.

Service

Comprehensive Boiler Solutions – From Planning to Lifetime Support

Pre-Sales Support:Expert Design Guidance: Help you select the optimal boiler model tailored to your industry needs.

Detailed Technical Documentation: Provide certificates, CAD drawings, consumption analysis, and boiler room planning.

Customized Solutions: Deliver complete system designs including installation material lists.

Competitive Pricing: Factory-direct rates with uncompromised quality.

After-Sales Assurance:Genuine Spare Parts: Original components with reliable supply.

Global Installation & Commissioning: Overseas engineer dispatch available.

On-Site Training: Ensure safe and efficient operation.

24/7 Online Support: Rapid response for any technical needs.

Warranty & Lifelong Care: One-year free maintenance and lifetime service support.

Parameter

| Model ltem | SZS4 | SZS6 | SZS10 | SZS15 | SZ20 | SZ25 | SZS30 | SZS35 | SZS40 | |

|

Rated evaporation (t/h) |

4 | 6 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | |

| Horsepower | 300hp | 400hp | 700hp | 1050hp | 1400hp | 1750hp | 2100hp | 2500hp | 2800hp | |

|

Rated working pressure (Mpa) |

1.0/1.25/ 1.6/2.5/3.0/3.82 | |||||||||

|

Rate steam temperature (ºC) |

145-450 | |||||||||

|

Feed water temperature (ºC) |

20 | 20 | 104/20 | 104/20 | 104/20 | 104/20 | 104/20 | 104/20 | 104/20 | |

|

heating area(m) |

Body | 90.22 | 125.6 | 205.56 | 216.84 | 271.5 | 285.24 | 392.34 | 457.7 | 523.12 |

| Economizer | 35.8 | 63.4 | 132.2 | 283.6 | 411.2 | 504.8 | 471.2 | 549.7 | 628.2 | |

| Condenser | 25.4 | 41.5 | 62.8 | 101.1 | 134.7 | 168.3 | 252.4 | 294.7 | 336.8 | |

| Available Fuel | lpg, cng, natural gas, biogas, coke gas, light oil, heavy oil, dual fuel | |||||||||

| Fuel consumption |

Natural gas (Nm3/h) |

288 | 432 | 720 | 1080 | 1440 | 1800 | 2160 | 2525 | 2881 |

|

Light oil (kg/h) |

244 | 372 | 620 | 930 | 1240 | 1550 | 1860 | 2079 | 2373 | |

| Thermal efficiency (%) | >98 | |||||||||

Relate Cases

Recommend Boiler

Oil Gas Smoke Tube Boiler

Horizontal oil gas fired fire tube boiler, Fully automatic, 3-pass wet back design

Vertical Oil Gas Fire Tube Boiler

Vertical oil gas fired fire tube boiler, Small footprint, low cost, quick into use

Once Through Oil Gas Boiler

Vertical oil gas fired water tube boiler, 0.1-4 ton/hr, quick steam generated in 3 mins

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler