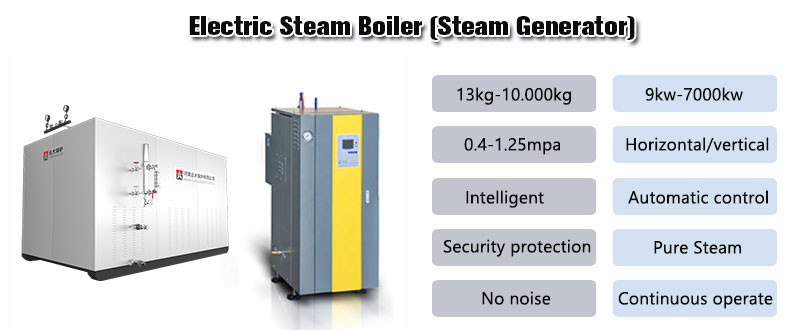

Electric Steam Generator, Electric Steam Boiler, Electric Hot Water Boiler

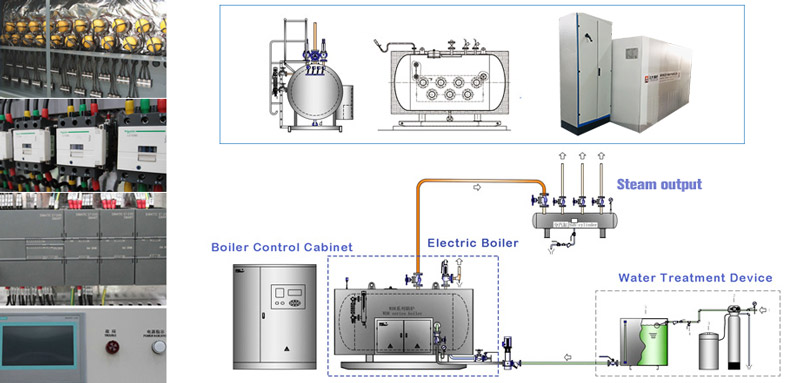

WDR LDR electric steam boiler adopts fully automatic operation, mainly composed of boiler proper, water treatment, control cabinet and so on. The boiler uses electricity as fuel, no need fuel arrangement, no chimney, and the thermal efficiency is above 98%, and it can meet the most stringent emission and fire protection standards.

| Fuel: | Electric |

| Capacity: | 12kg-10000kg, 9kw-7000kw |

| Work Pressure: | 3-25bar, 0.3-2.5Mpa |

| Heat Temperature: | 0-300℃ |

| Applied Industries: | Food, Beverage, Textile, Garment, Paper, Hotel, Dairy, Washing ironing, Pharm, Packaging, Labeling, Chemical, Coating, Concrete Curing, Sauna etc |

Introduction

Yuanda Boiler offers a range of electric steam boiler and electric steam generator. Steam capacity from 10 kg/hr to 10,000 kg/hr(equal to 9kw to 7000kw), designed to provide high-temperature heat energy for industrial production efficiently and environmentally.

Widely use for food and beverage machinery, washing and ironing equipment, building materials and plastics machinery, papermaking and printing equipment, chemical extraction equipment, pharmaceutical equipment, etc.

Product Series: WDR horizontal electric steam boiler, LDR electric steam generator, JDR clean/pure electric steam generator.

LDR vertical electric steam boiler, also known as steam generator, electric steam generator, small electric boiler, stainless steel steam generator. Cabinet design style, Composed of electric heating elements, components, drums, accessories, strong and weak current controlsystems, etc.

Main characteristics:

● Power 9kw-350kw, steam capacity 13kg-500kg

● Produce steam within 3-5 minutes

● Pressure up to 10 kg/cm²

● One key to start

● Small food print

● All internal piping and boiler control system has been connected before delivering the factory

The steam is generated by an electric resistor heating flange inside the boiler shell. The units are skid-mounted complete with feed water tank, water treatment and control panel. The complete factory pre piping and wiring ensures quick and easy installation on site.

Main characteristics:

● Power 210kw-7000kw, steam capacity 300kg-10.000kg

● Produce steam within 20 minutes

● Pressure up to 20 kg/cm²

● Separate boiler body and control cabinet

● Automatic blow-down system

● Large load adjustment range

● All internal piping and boiler control system has been connected before delivering the factory

1. Electric operation does not require gas/oil supply and chimney system

2. Pipes and wires pre-installed in the factory

3. Control panel with system visualization

4. Individual designed as per customer needs

5. Good accessibility for maintenance and checks due to the removable inspection box and removable panels

6. Internal steam-water seperator, high amount of steam

7. No pollution, no noise

8. No combustion chamber, no chimney, no heat loss, thermal efficiency is above 98%

9. Multiple protection voltage, water level, power supply and pressure

10. The boiler heating group can be set as required

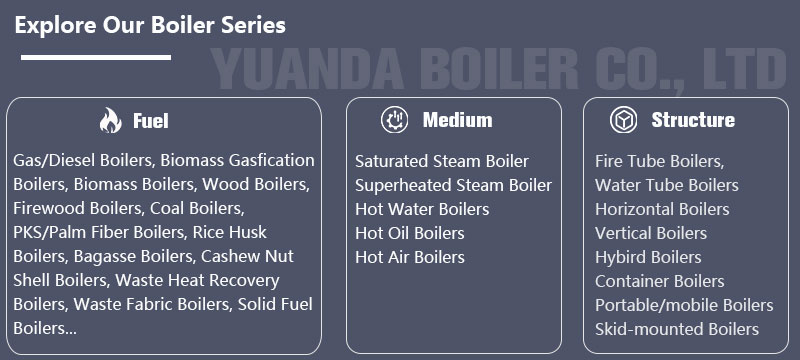

Yuanda Boiler, leading A-Grade boiler and incinerator manufacturer, holding ASME, CE, ISO, EAC, DOSH certification.

We provide Steam Boiler, Hot Water Boiler, Thermal Oil Boilers and Waste Incinerator.

Available Fuels: Gas, Oil, Biomass Wood, Palm Kernel Shell&Fiber, Bagasse, Solid Waste, Waste Fabric, Coal and Electric.

Quality Control

Service

Comprehensive Boiler Solutions – From Planning to Lifetime Support

Pre-Sales Support:Expert Design Guidance: Help you select the optimal boiler model tailored to your industry needs.

Detailed Technical Documentation: Provide certificates, CAD drawings, consumption analysis, and boiler room planning.

Customized Solutions: Deliver complete system designs including installation material lists.

Competitive Pricing: Factory-direct rates with uncompromised quality.

After-Sales Assurance:Genuine Spare Parts: Original components with reliable supply.

Global Installation & Commissioning: Overseas engineer dispatch available.

On-Site Training: Ensure safe and efficient operation.

24/7 Online Support: Rapid response for any technical needs.

Warranty & Lifelong Care: One-year free maintenance and lifetime service support.

Parameter

| Model | Rated capacity(kg) |

Input power (kw) |

Rated pressure(Mpa) | Steam temperature(℃) | Thermal efficiency(%) |

| LDR0.013-0.7 | 13 | 9 | 0.7 | 171 | 99.9 |

| LDR0.017-0.7 | 17 | 12 | 0.7 | 171 | 99.9 |

| LDR0.025-0.7 | 25 | 18 | 0.7 | 171 | 99.9 |

| LDR0.035-0.7 | 35 | 24 | 0.7 | 171 | 99.9 |

| LDR0.05-0.7 | 50 | 36 | 0.7 | 171 | 99.9 |

| LDR0.065-0.7 | 65 | 48 | 0.7 | 171 | 99.9 |

| LDR0.075-0.7 | 75 | 54 | 0.7 | 171 | 99.9 |

| LDR0.085-0.7 | 85 | 60 | 0.7 | 171 | 99.9 |

| LDR0.1-0.7 | 100 | 72 | 0.7 | 171 | 99.9 |

| LDR0.11-0.7 | 110 | 80 | 0.7 | 171 | 99.9 |

| LDR0.125-0.7 | 125 | 90 | 0.7 | 171 | 99.9 |

| LDR0.15-0.8 | 150 | 108 | 0.8 | 175 | 99.9 |

| LDR0.18-0.8 | 180 | 126 | 0.8 | 175 | 99.9 |

| LDR0.2-0.8 | 200 | 144 | 0.8 | 175 | 99.9 |

| LDR0.25-0.8 | 250 | 180 | 0.8 | 175 | 99.9 |

| LDR0.3-0.8 | 300 | 216 | 0.8 | 175 | 99.9 |

| LDR0.4-0.8 | 400 | 288 | 0.8 | 175 | 99.9 |

| LDR0.5-0.8 | 500 | 360 | 0.8 | 175 | 99.9 |

| WDR0.5-1.0 | 500 | 360 | 1 | 184 | 98 |

| WDR1.0-1.0 | 1000 | 700 | 1 | 184 | 98 |

| WDR2-1.0 | 2000 | 1400 | 1 | 184 | 98 |

| WDR3-1.25 | 3000 | 2100 | 1.25 | 194 | 98 |

| WDR4-1.25 | 4000 | 2800 | 1.25 | 194 | 98 |

| WDR5-1.25 | 5000 | 3500 | 1.25 | 194 | 98 |

| ....... | |||||

| WDR10-1.25 | 10000 | 7000 | 1.25 | 194 | 98 |

Relate Cases

Recommend Boiler

DZL Biomass boiler

Single drum chain grate burning solid fuel boiler, water&fire tube boiler, fully automatic

WNS Oil Gas Fired Boiler

Horizontal 3-pass fire tube boiler with famous burner. Energy saving

DZH Coal/Wood Boiler

Traveling grate boiler, hand-feed, running stable, suitable for bigger solid fuel

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler