diesel boiler | fire tube boiler | wet back boiler

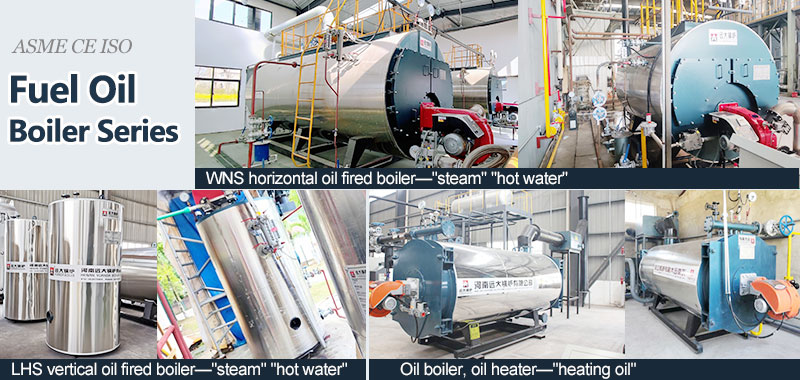

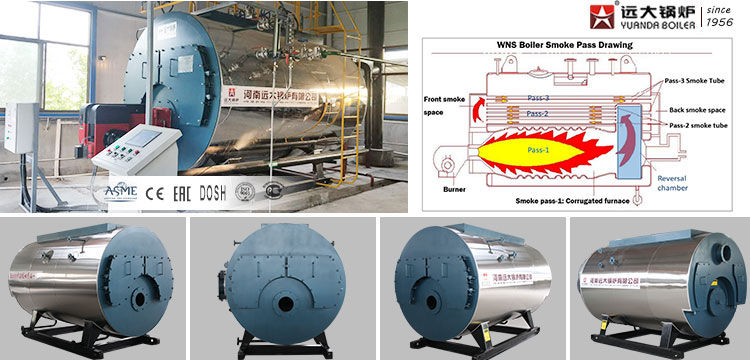

Fuel oil fired boiler is the 3-pass wet back boiler, can produce steam or hot water. This type boilers are fully automatic, safe, energy saving and designed to operate on a wide range of liquid and gaseous fuels like heavy oil, light oil, gas, and dual fuel options.

| Output: | steam, hot water |

| Capacity: | 0.2 to 40 Ton/h, 120 to 14,000 KW |

| Horsepower | 10hp to 2500hp |

| Pressure | 0-38bar, 0-3.8mpa |

| Applied Industry: | food&beverage, dairy, feed, textile, paper, chemical, package, refinery, pharm, building material, hotel etc |

Introduction

Industrial oil fired boiler can generating steam, hot water or hot oil for processing. It has won most of the market with its advantages of low emission, long life and high degree of automation.

Yuanda Boiler fabricating fire tube oil fired boiler, vertical oil boiler, thermal oil heating boiler:

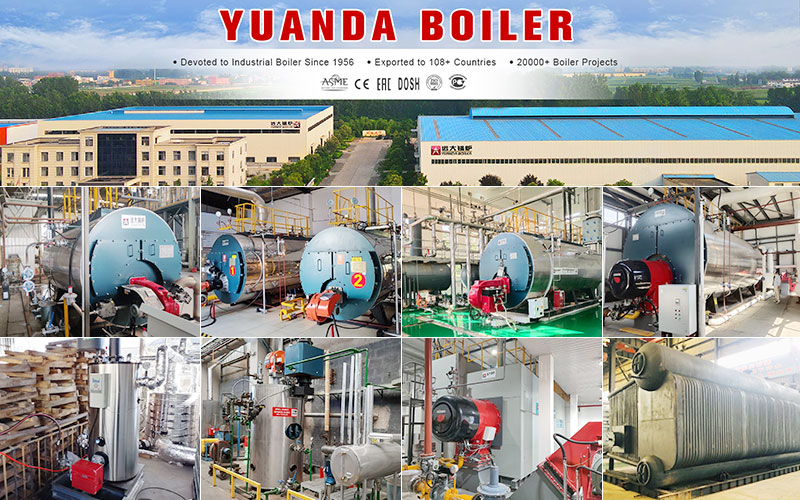

Yuanda devoted to industrial boilers since 1956. With ASME CE EAC DOSH GOST CRN quality certificate, exported to all over the world.

It adopts three-pass wet-back structure, large corugated furmace and thread smoke tube technology, 5-th inter-lock protection, equipped with intemational first-level brand burners, valves, instruments, advanced expansion welding technique. Independently developed high-matching PLC control system to realize muitiple linkages, protects the boiler long uselife & safety running.

Fuel: natural gas, lpg, diesel, heavy oil, dual fuel and exhaust gas.

LHS LSS Small gas/diesel boiler, vertical boiler, gas/diesel steam generator and hot water generator.

Suitable for 0-2ton, 0-2000kg, 0-150hp.

●High Security, Safe Operation;

①Anti-dry heating system with 5-th water level detect;

②Four stages pressure protection;

③Explosion-proof door with fire viewer;

④Remote monitoring system.

●High Efficiency, Save Fuel & Running Cost;

①Large corrugated furnace, patent design three pass smoke tubes;●Long Using Life and Convenient for Maintenance

①Wet-back reverse flame chamber;●Packaged Boiler, Less Installation Work

Easy for transportation and installation, also could be pre-installed in the factory, customers only connect water, electricity, fuel at site

Quality Assurance

Our Service

Pre-sale Service:

1. Design一We help customer to choose the best boiler model according to the different requirements of different industries.

2. Drawing and files一Supply quality certificates, factory-inspect, fuel consumption calculation, cost analysis, foundation drawings, layout drawings, boiler room drawings nased on your needs, etc.

3. Technical Solution一Design completed boiler solution with installation materials for your company.

4. Competitive Price一As one boiler factory, we have lowest price and high quality.

After-sale Service:1. Provide a full range of boiler and original spare parts.

2. Overseas engineers installation and commissioning service is available.

3. Training in site, to ensure safe operation.

4. 24 hours online, quick respond.

5. Free maintenance and repair for one year and lifetime service.Parameter

| Model | Horsepower | Rated steam output | Rated pressure | Rated temperature | Feed water temperature | Fuel consumption | |

| (hp) | (Ton/hr) | (Mpa) | (℃) | (℃) | Light diesel oil(kg/h) | Natural gas(Nm3/h) | |

| LSS0.1 | 7hp | 0.1 | 0.4/0.7 mpa | 130~171 | 20/105 | 6.7 | 7.3 |

| LSS0.2 | 15hp | 0.2 | 130~171 | 20/105 | 12.8 | 17 | |

| LSS0.3 | 25hp | 0.3 | 130~171 | 20/105 | 19.2 | 25.5 | |

| LHS0.5/LSS0.5/WNS0.5 | 35hp | 0.5 | 130~171 | 20/105 | 32 | 42.5 | |

| LHS0.7/WNS0.7 | 50hp | 0.7 | 130~171 | 20/105 | 49.5 | 51 | |

| LHS1/WNS1 | 65hp | 1.0 | 0.4/0.7/1.0/1.25/1.6/2.5/3.0 mpa | 130~185 | 20/105 | 70 | 80 |

| LHS1.5/WNS1.5 | 100hp | 1.5 | 130~185 | 20/105 | 108.7 | 115.4 | |

| LHS2/WNS2 | 125hp | 2 | 130~185 | 20/105 | 135.2 | 150.4 | |

| WNS3 | 200hp | 3 | 130~226 | 20/105 | 192.9 | 212.1 | |

| WNS4 | 250hp | 4 | 130~226 | 20/105 | 258.2 | 283.4 | |

| WNS5 | 300hp | 5 | 130~226 | 20/105 | 323.5 | 354.7 | |

| WNS6 | 350hp | 6 | 130~226 | 20/105 | 388.6 | 424.2 | |

| WNS8 | 500hp | 8 | 130~226 | 20/105 | 514.6 | 566.3 | |

| WNS10 | 600hp | 10 | 130~226 | 20/105 | 641.7 | 707.8 | |

| WNS12 | 720hp | 12 | 130~226 | 20/105 | 768.9 | 849.3 | |

| WNS15 | 900hp | 15 | 130~226 | 20/105 | 960.1 | 1061.7 | |

| WNS20 | 1200hp | 20 | 130~226 | 20/105 | 1276.2 | 1415.8 | |

| Model |

Rated heating capacity (mw) |

Rated working pressure (Mpa) |

Output water temperature (℃) |

Return water temperature (℃) |

Fuel consumption | |

| Light diesel oil(kg/h) | Natural gas(Nm3/h) | |||||

| WNS 0.35 | 0.35mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 31.6 | 36.6 |

| WNS 0.7 | 0.7mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 60.4 | 69.3 |

| WNS 1.4 | 1.4mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 122.8 | 146.1 |

| WNS 2.1 | 2.1mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 192.3 | 227.1 |

| WNS 2.8 | 2.8mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 246.1 | 286.5 |

| WNS 4.2 | 4.2mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 367.1 | 412.6 |

| WNS 5.6 | 5.6mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 490.2 | 543.7 |

| WNS 7.0 | 7.0mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 593.6 | 660.7 |

| WNS 10.5 | 10.5mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 936.5 | 998.8 |

| WNS 14 | 14mw | Atmospheric pressure/0.7/1.0/1.25/1.6 | 85~130 ℃ | 70/60 ℃ | 1200.8 | 1330.7 |

| Note: for place limited, we didn't list all models, if you need other capacity, pressure, fuel, please send us inquiry directly, we will send you detailed parameter. | ||||||

Relate Cases

Send Your Message

Please leave message with your contacts and the product you need. We will reply within 6 hours. Thanks.

Steam Boiler/Generator

Hot Water Boiler

Thermal Oil Boiler