PRODUCT LIST

APPLICATIONS

2025/07/05

1. Structural Characteristics of Chain Grate and Reciprocating Grate(step garte, pusher grate)

The structure of the chain grate is relatively intuitive, and its components include active chain rings, grate splints, grate pieces, sprockets, chains, brackets, slag blocking devices, and front and rear axle devices. The chain is driven by the sprocket, which in turn pushes the grate pieces forward to achieve fuel transportation and combustion.

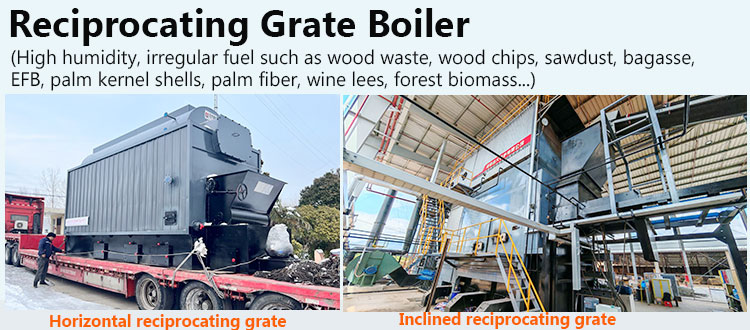

In contrast, the reciprocating grate is special designed for biomass fuel boilers, and its structure is more complex, the difficulty of manufacturing and installation is also increased accordingly. It is mainly composed of movable grate pieces, fixed grate pieces, and transmission mechanisms. The reciprocating grate causes the fuel to roll and move forward on the grate through the reciprocating motion of the movable grate pieces on the fixed grate pieces, thereby realizing the transportation and combustion of the fuel.

2. Comparison of the Advantages and Disadvantages of Chain Grates and Reciprocating Grates

Chain grates are easy to operate and run stably, but they have strict requirements on fuel. For example, the fuel particle size needs to be moderate. Too fine may lead to incomplete combustion, and too coarse may affect ventilation and combustion effects. In addition, chain grates are not suitable for burning fuels with too high or too low moisture content, otherwise it will affect the stability and efficiency of its combustion. It is more suitable for burning high-quality coal, bituminous coal and other fuels with high volatile matter and high ash melting point.

Reciprocating grates show stronger fuel adaptability and can cope with fuels of different qualities, including inferior coal and high ash coal. By adjusting the movement amplitude and frequency of the active grate slices, the combustion effect of different fuels can be optimized. In addition, the reciprocating grate can flexibly respond to load changes and maintain a stable combustion state. Due to its unique reciprocating motion design, the fuel and air are mixed more fully, thereby improving the combustion efficiency.

3. Cost Analysis of Chain Grate and Reciprocating Grate

The equipment cost of chain grates is relatively low, but the combustion efficiency is slightly inferior to that of reciprocating grates, resulting in relatively high operating costs. At the same time, chain grates have more parts, and they need to be regularly checked for wear and tear, which requires a large maintenance workload, thereby increasing maintenance costs.

In contrast, although the equipment cost of reciprocating grates is higher, their combustion efficiency is better and their operating costs are relatively low. In terms of maintenance, the wear and deformation of the grate plates are mainly checked, and the workload is relatively small.

In general, chain grates and reciprocating grates each have their own adaptability and advantages. When choosing a coal or biomass steam boiler, you should base it on actual needs and fuel characteristics.