PRODUCT LIST

APPLICATIONS

2019/11/08

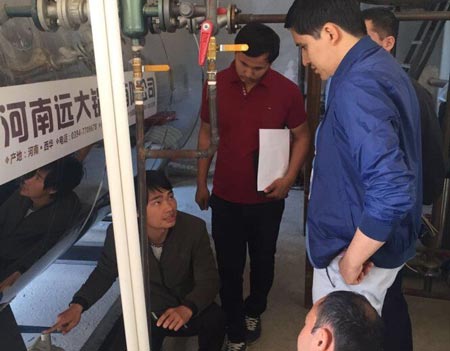

Last month, Yuanda Boiler International Trade Manager and engineers conducted a return visit to the boiler site in Southeast Asia including Indonesia, Cambodia, Thailand, and the Philippines etc. Customers are generally very satisfied with the Yuanda service. whats more, yuanda engineer also provided maintenance and repair training for the boiler user.

So what should we pay attention to in the daily maintenance of the Yuanda boiler? What preparations should be made before the steam boiler is overhauled? Let's take a look at:

Preparation before maintenance

1. Stop the furnace. No matter what time the steam boiler is overhauled, it is necessary to ensure that the boiler can be shut down before the inspection. The boiler in operation cannot be directly inspected, and the boiler condition can only be analyzed through the instrument data.

2. Power off. Steam boilers, such as burners, must use electricity or water supply pumps, etc. These devices must also be powered off.

3. Cut off the gas. Gas fired steam boilers must be shut off, flammability and other ignition points are low, whether it is found abnormal boiler or daily maintenance to ensure that the gas has been cut.

4. Tools. The tools for steam boiler maintenance are indispensable, and there are other auxiliary materials. These tools must be prepared. The second is to be placed on the side of the boiler to prevent it from falling or falling into the boiler.

5. Environment. Ensure that the surrounding environment of the boiler reaches the working conditions.

Steam boiler overhaul attention

In the maintenance of steam boilers, attention should be paid to ventilation, monitoring, lighting, component disassembly, and sensitive components, as follows:

1. Ventilation and monitoring should be ensured when the maintenance personnel enter the boiler. The manholes on the drums and containers and the hand holes on the headers are all open. When the personnel enter the flue or the combustion chamber, they should be well ventilated.

2. Lighting, boiler drum and flue maintenance should be done well, the lighting voltage should not exceed 24V, which is the requirement in the relatively humid conditions, if the ambient dry lighting voltage can not be higher than 36V, the main attention It is not possible to use open flame lighting in boilers and containers.

3. Parts and boilers are forbidden to be pressed and disassembled and connected. It is necessary to discharge all the pressure before it can be carried out.